GENERAL FEATURES OF TABLE TYPE SCAFFOLDING SYSTEM:

What is Table type H load Scaffolding? Table Type Scaffolding System is the most preferred system among formwork scaffolding systems. It is suitable for all kinds of structures such as underfloor formwork systems, bridges, warehouses, irregular beam systems, heavy reinforced concrete systems.

It has a high carrying capacity, is easy and safe to install, thanks to its standard sized framed structure made of 60.0/3.0mm or 60.0/4.0mm Pipes. It is a practical scaffolding system that saves labor with less material.

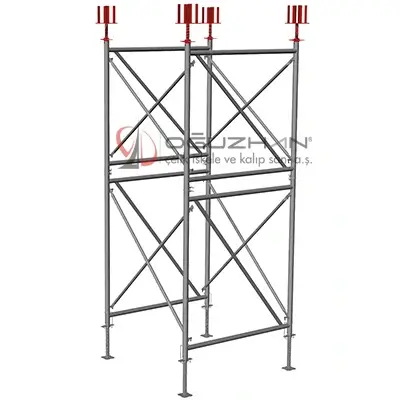

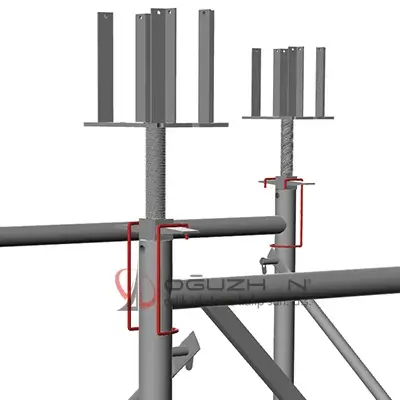

Table Scaffolding System: Consists of Lower Adjustment Shafts, H Frames, Double Cross Bar, Intermediate Nipple and Upper Adjustment Shafts. (Headings are in the form of 4-Way Header or U Header.)

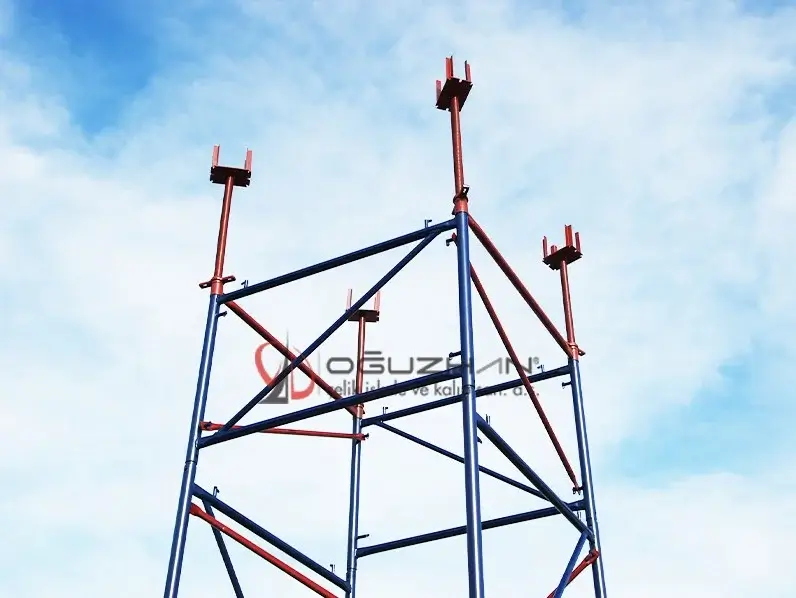

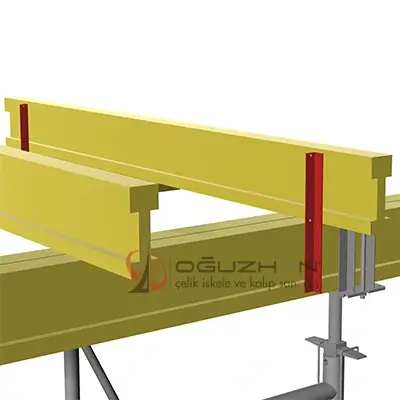

The table scaffolding system is also installed in the form of towers. The connection of the frame and double cross bars is formed by pin lock systems. The vertical connection between the frames is provided by intermediate nipples. With this sequence, the scaffolding system is raised to the desired height. Finally, 10x10 timbers or reinforced beam H20s are placed on top of the upper shafts, whose elevations are adjusted, in order to form the mold surface.

Frames used in Table Type are in Standard 110/150, 150/150, 180/150 and 200/150 sizes. The double diagonal distances between the frames can be created at intervals of 100cm, 125cm, 150cm, 175cm, 200cm, 225cm and 250cm according to the specifications of the project.

Our Table Scaffolding Materials are produced as OĞUZHAN® brand in accordance with TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials.

The pipes used in the production of table scaffolding are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard.

Under-formwork Table Scaffolding System; It consists of Lower Adjustment Rods, H Frame, Double Cross Rods, Intermediate Nipple Element and Upper Adjustment Rods..

Installation: The ground on which the scaffolding system will be installed is made ready for installation, Lower adjustment shafts are placed and adjusted according to the tower dimensions, H Frames selected according to the height of the tower are placed, Double braces that provide the connection between the H frames are connected, If more frames are to be added according to the tower height, search between two frames. The nipple element is placed and the installation continues in the same way, Upper Adjustment Shafts are placed to adjust the formwork elements, the tower installation is completed after the Shaft Head adjustments are made.

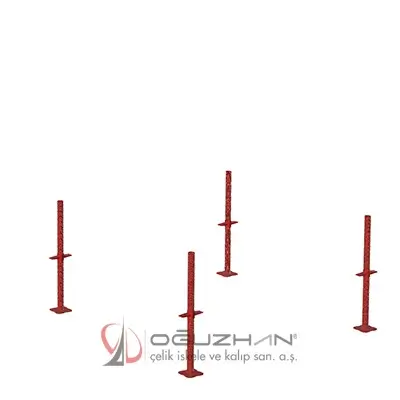

Lower Adjustment Shafts: It is the first element required to start the installation of the scaffolding system at the determined elevations. The height can be adjusted according to the working condition of the ground and scaffolding system. The Base Plate, which should have an area of at least 15cm2, is manufactured from 8.0mm sheet metal with the dimensions of 12.5x12.5cm. 48.0/5.0mm Pipes are threaded and become a shaft and are used together with the adjustment nut. It becomes the lower adjustment shaft by fixing the shafts with the base plate by welding. They can be 50cm, 75cm, 100cm and 120cm in length.

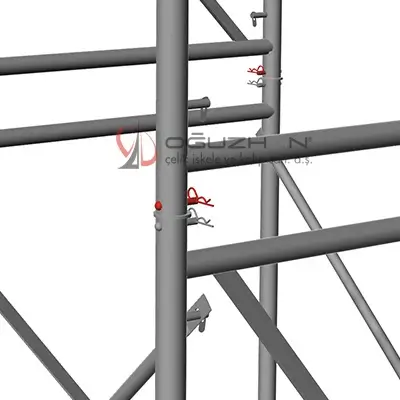

H Frame: It is the main carrier element of the table scaffolding system. The vertical parts of the H frame are made of 60.0/3.0mm or 60.0/4.0mm steel pipes, the horizontal parts are made of 48.0/3.0mm steel pipes and the support part is made of 34.0/2.0mm steel pipes. Vertical pipes, horizontal pipes and support parts are adjusted to be combined, 4 pin lock systems are added and all materials are fixed to each other with the help of welding. In this way, H Frame production is realized. Its dimensions are 110x150cm, 150x150cm, 180x150cm and 200x150cm as standard. With the pin lock system, they are connected with double cross members.

Double Cross Bar: It is one of the main elements required for the safe installation of the system. It is manufactured from 34.0/2.0mm or 34.0/2.5mm steel pipes. The two pipes are combined with screws from the middle parts and made into a double cross. In order for H Frames to be connected to the pin lock places, both ends of the pipes are crushed and holes are drilled in size to pass into the pins. Their height is adjusted according to the distance between 2 H Frames. Double cross for 0.75m spacing, double cross for 1.0m spacing, double cross for 1.25m spacing, double cross for 1.50m spacing, double cross for 1.75m spacing, double cross for 2.0m spacing, 2, They are produced as double cross for 25m intervals and double cross for 2.5m intervals.

Intermediate Nipple: In the table scaffolding system, the frames do not have end pipes or interlocking pipe systems. In this system, a coupling piece, that is, a nipple element, is used between the frames. Nipple is manufactured from 48.0/3.0mm steel pipes. Its height is between 15-20 cm and there are camber parts in the middle of the frame systems. The pipe sections enter the frames from the top and bottom up to the camber part and provide the connection. Connection security is ensured by using pins / cotter pins in the holes drilled at a distance of 5 cm from the ends of the frame and the intermediate nipple piece.

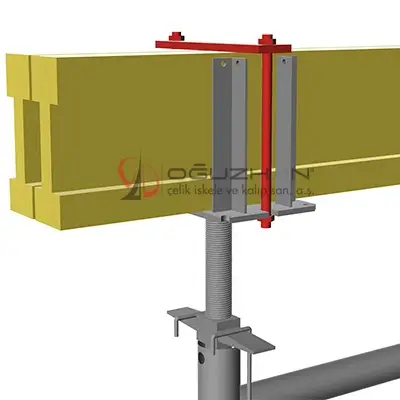

Upper Adjustment Spindle: It is the last element required for adjusting the scaffolding system according to the level of the formwork. Height can be adjusted according to working conditions. Shafts are produced by threading on 48.0/5.0mm pipes, the head system is fixed on the shafts by welding, used together with the adjusting nut. There are 4 types of headers: Flat Head, U Head, Beam Head (T Head) and Four Way Head. They can be 50cm, 75cm, 100cm and 120cm in length.

annotation

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |