GENERAL FEATURES OF H TYPE SYSTEM:

What is H Type scaffolding ? H Type scaffoldingsystem is also known as framed scaffolding system. It can be used in most construction works, in all kinds of facade operations such as paint, plaster, insulation, etc. to be made on the building surface. It is one of the most common scaffolding systems.

In this scaffolding system, unlike flanged scaffolding, the main carrier, that is, vertical elements, is in the form of a frame, and the connection to be made with horizontal and cross elements is formed with the help of pin locks.

There are 3 pin lock systems in total on vertical frames. The pins are 2 pieces facing inwards at the parts where the horizontal members will be connected, and 1 facing out for the placement of the cross members. These pin lock systems must be welded securely and securely to the vertical frame.

Since the materials used in the H Type scaffolding system are always produced in standard sizes, its installation is fast and practical. Its cost is more affordable than others. There is no need to create additional labor or force (using a hammer) for installation. Much work can be done with less material. Since it is easy to install, labor is saved.

Our H Type Scaffolding Materials are produced under the brand name of OĞUZHAN® in accordance with TS EN 12810 Standard for Facade Scaffolds Consisting of Pre-built Components and TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials.

The pipes used in the production of H Type Scaffolding are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard. Afterwards, the scaffolding elements were subjected to Durability, Loading, Deflection and Sphere Throwing tests according to TSE 12810-2 and TSE 12811-1 Standards.

TECHNICAL DETAILS :

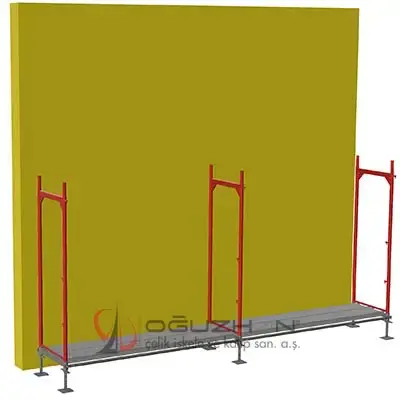

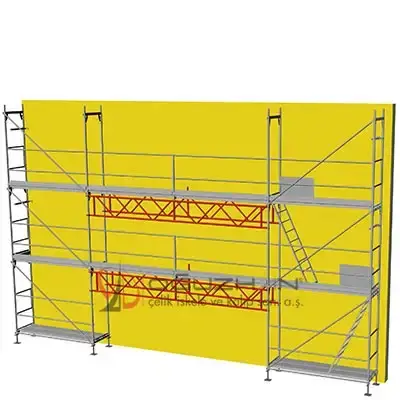

H Type Scaffolding System: It consists of Lower Adjustment Shaft, Initial Horizontal, Vertical Frame, Horizontal Element, Cross Member, Walking Platform (Sheet Plank), Heel (Shin Rail), Platform with Ladder, Side Railing, Overhang Console and Accessories.

In H Type Scaffolding System; Lower adjustment shafts 38.0/4.0mm, Vertical frames 48.3/3.0mm, Horizontal members 34.0/2.0mm, Cross members 40.0/2.5mm in sections according to TSE EN 10219-2 Structural Steel Pipe Standard It is manufactured from suitable pipes.

All elements on the scaffolding system have been subjected to Durability, Loading and Deflection tests according to TSE 12810-2 and TSE 12811-1 Standards. Platforms were tested by throwing a 100 kg Sphere from a height of 2.50 m.

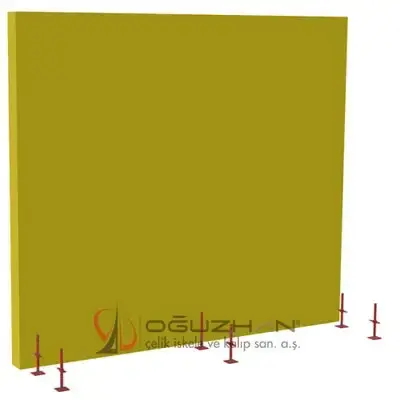

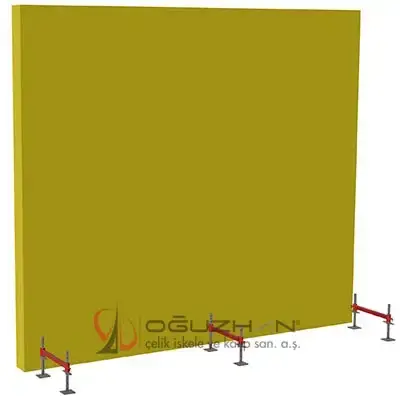

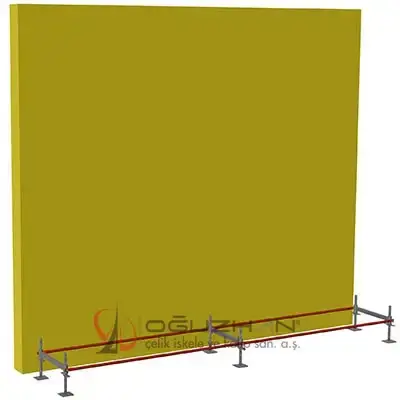

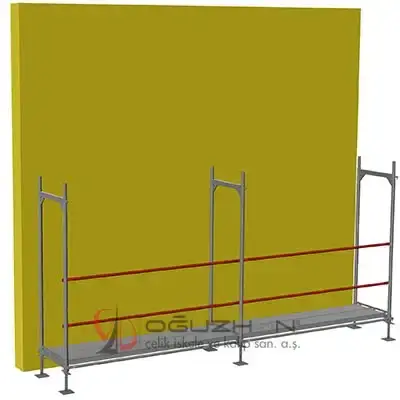

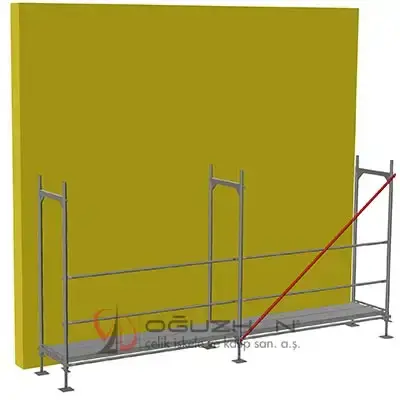

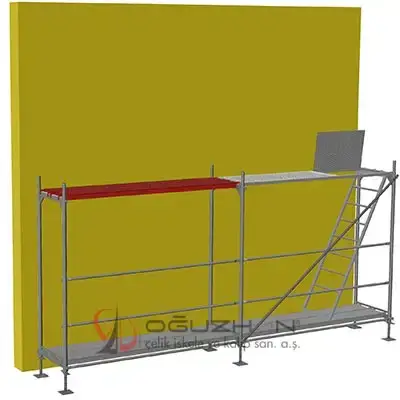

Installation: Lower adjustment shafts are adjusted, Initial horizontals are placed on two adjustment shafts, The lowest horizontal elements are added, The scaffolding system is leveled, Walking platforms are placed under the stairs, Vertical frames are placed, Horizontal elements are placed on the pins on the frames, Cross elements are placed on the initial horizontal and It is placed on pins on the vertical frame, Ladder platform is placed, Metal platforms are placed in double rows, Horizontal and cross members are placed in the upper row, Heels are placed, These processes are repeated for every 2.0 m height, respectively, wall connection is performed for security purposes.

vertical frames ; They are the main carrier elements. It is formed by welding 48.3/3.0mm steel pipes with 20/40/2.0mm from the bottom and 40/60/2.0mm from the top and becoming a frame. Standard frames are 2.00 meters long and 75-80 cm wide. The connection parts are provided with welded pin locks, two for the horizontal members on the inside and one for the cross members on the outside.

Horizontal elements; They act as balusters, connecting the vertical frames. It is made of 34.0/2.0mm steel pipes. In order for them to make connections on the scaffolding system, both ends are crushed and holes are drilled in the size for the pins to pass through. Their length is 2,50 meters as standard. They can also be manufactured as 2.50mt, 1.80mt, 1.50mt in accordance with the conditions.

Cross members ; It is used to ensure the safety of the system against external forces and to prevent it from moving. It is made of 40,0/2,5mm steel pipes. In order for them to make connections on the scaffolding system, both ends are crushed and holes are drilled in the size for the pins to pass through. Their height should be in accordance with the standard area of 200 cm vertically and 250 cm horizontally. They can also be produced for special sizes if required.

Platforms create work areas on the scaffold. They consist of 1.50mm Sheet and Head parts. After the rolled sheet is shaped with a Rollform Machine, it is joined with the head parts by means of gas metal arc welding. Finally, it is taken to the galvanization process. As a standard, they can be 2.50 meters in length and 25-35 cm in width.

Platforms with stairs are used on the scaffolding to pass between floors. On its frame made of profile iron, there is a platform surface made of sheet metal such as the head, hooks, ladder part and walking platform. They can be produced in two different types depending on the dimensions of the scaffolding, with cover, with plank or with a landing. Their length is adjusted as 2,50 meters in standard dimensions.

Scallops and heels are both names given to the same material. They are the elements used to prevent the material from falling over the scaffolding platforms. It is formed by forming 1.5mm galvanized coil sheets with a rollform machine. Their height is at least 15 cm, their length is standard 2.50 meters. They can also be produced in special sizes. It is suitable for use on any platform.

Overhead Consoles create additional workspaces to optimize working conditions on the scaffold. It is manufactured from 48,3/2,50mm pipe, 40/60/2.0mm Iron Profile and Connection clamps. They are used by connecting to the scaffolding system from the clamp parts. Consoles; It can be produced in 0.35mt, 0.50mt, 0.70mt, 0.75mt, 1.00mt sizes.

Wall fasteners are used to fix the scaffolding system and provide stability. They provide security between the wall and the scaffold, thanks to their mechanisms consisting of 48.3/3.00mm pipe, hook and rod parts.

Among the materials used in the scaffolding system, accessories are materials that increase safety and ease the workflow. Connection pipe, Clamp systems, Intermediate cover grates etc. can be cited as examples.

In the part of the required standards and legal regulations in scaffolding systems;

TS EN 12810-1 Facade Scaffolding Systems Consisting of Pre-built Components (Part 1: Product Properties),

TS EN 12810-2 Facade Scaffolding Systems Consisting of Pre-built Components (Part 2: Special Structural Design Methods),

TS EN 12811-1 Temporary Work Equipment (Part 1: Scaffolding - Performance Requirements and General Design),

TS EN 12811-2 Temporary Work Equipment (Part 2: Material Information),

TS EN 12811-3 Temporary Work Equipment (Part 3: Loading Tests) Standards are discussed.

annotation

Advantages of H scaffolding;

Since the system consists of welded frames, it can be assembled faster.

Horizontal and cross pipes are lighter and more practical.

There is no need to use a hammer in assembly.

250 cm long walking platforms are lighter.

It is a more cost-effective system. Security scaffolding prices are lower.

H Scaffolding Prices;

We cannot share H Type scaffolding prices on the website. Due to many factors, there may be instantaneous decreases and increases in the prices of H piers. In order to avoid any inconvenience, we request you to learn the current prices of H type scaffolding directly from our factory. You can find all the necessary information on our contact page.

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |