GENERAL FEATURES OF SINGLE FACE CURTAIN MOLDING SYSTEM:

Single Sided Curtain Formwork is one of the systems that has the heaviest iron component among the formwork systems and is one of the most durable systems against the weight of concrete coming into the formwork.

Requires work on one-sided mold surface; It is used in works such as Mass Concrete Curtain Forms, Retaining Wall Formworks, Highway Works, High Foundation Formworks, Engineering Structures and Insulated Formwork systems.

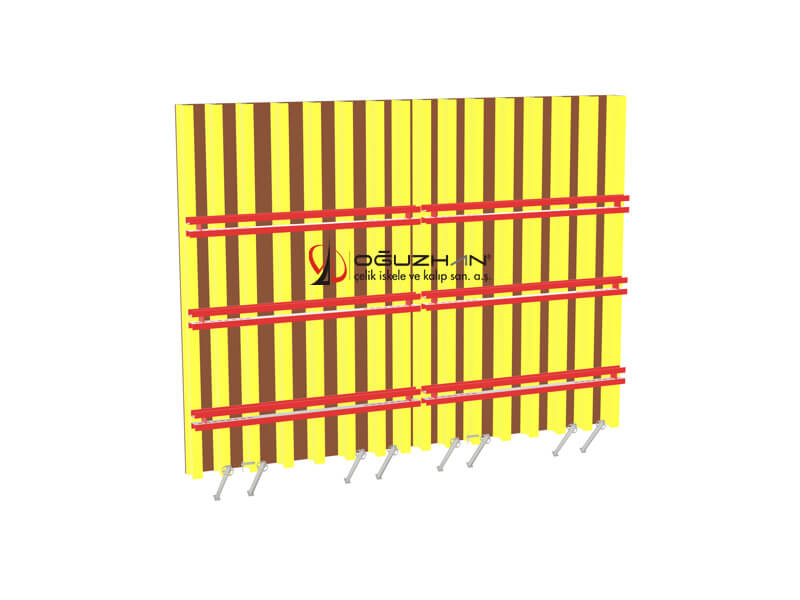

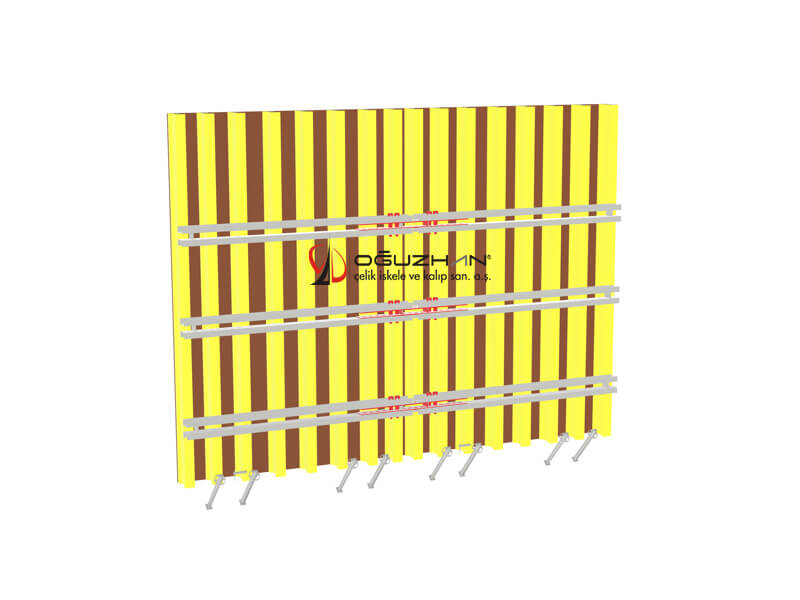

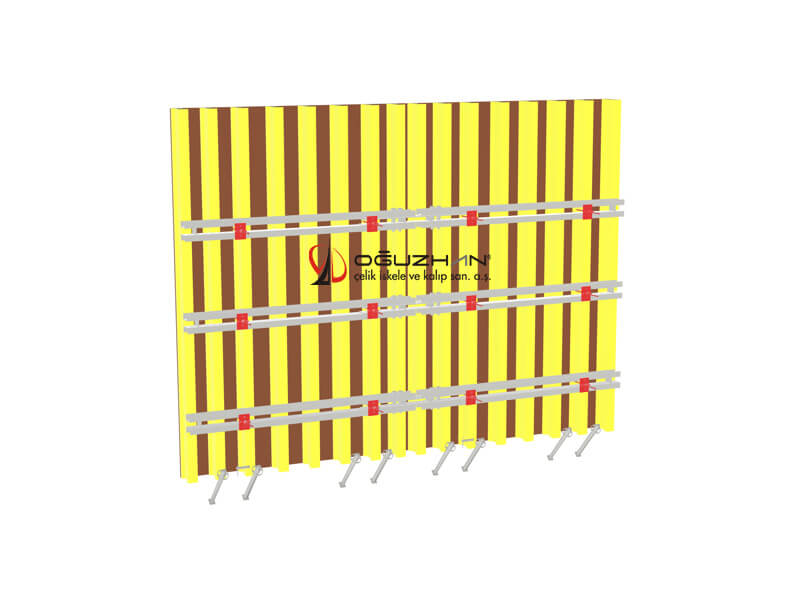

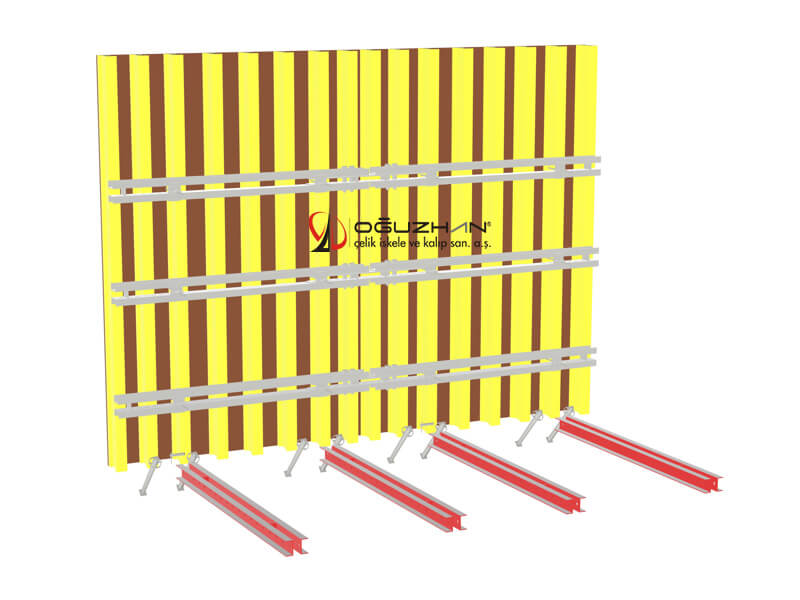

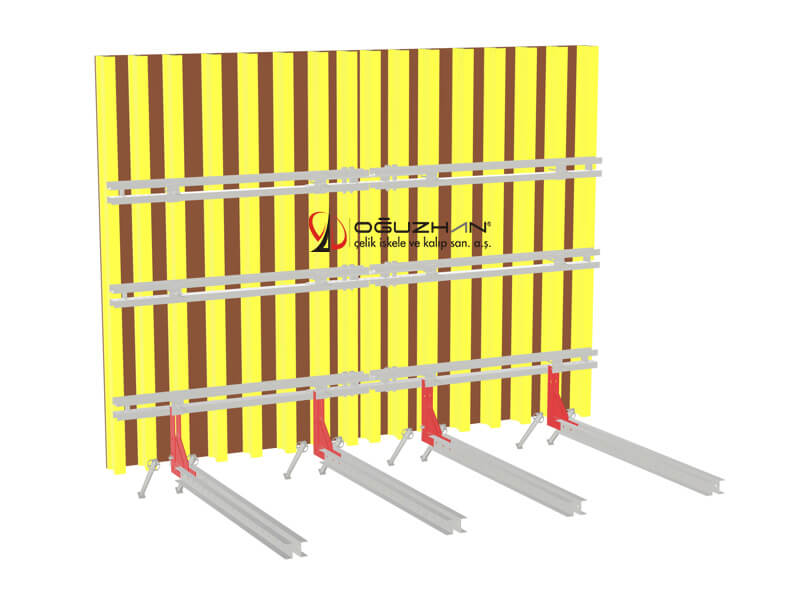

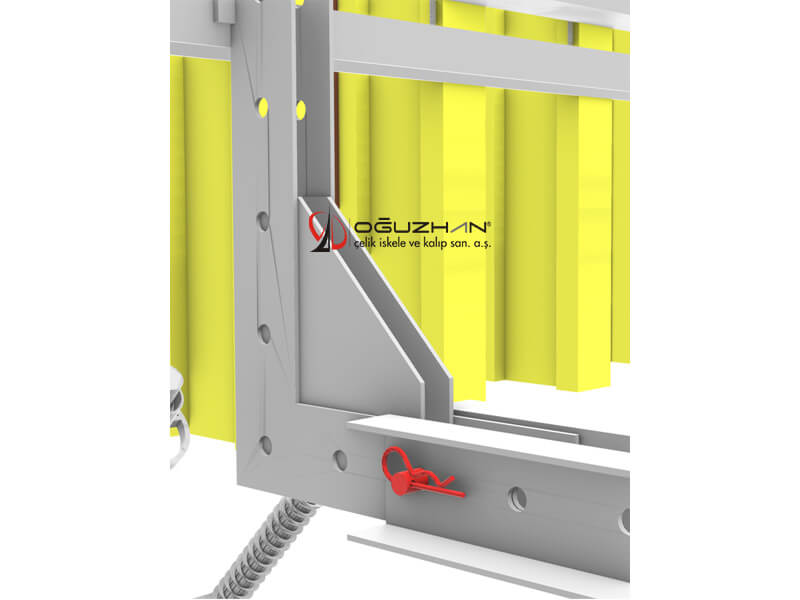

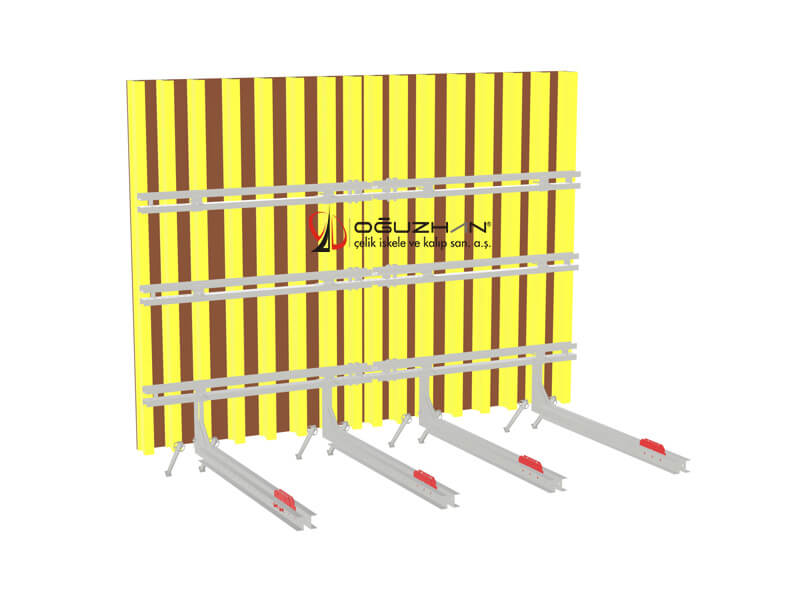

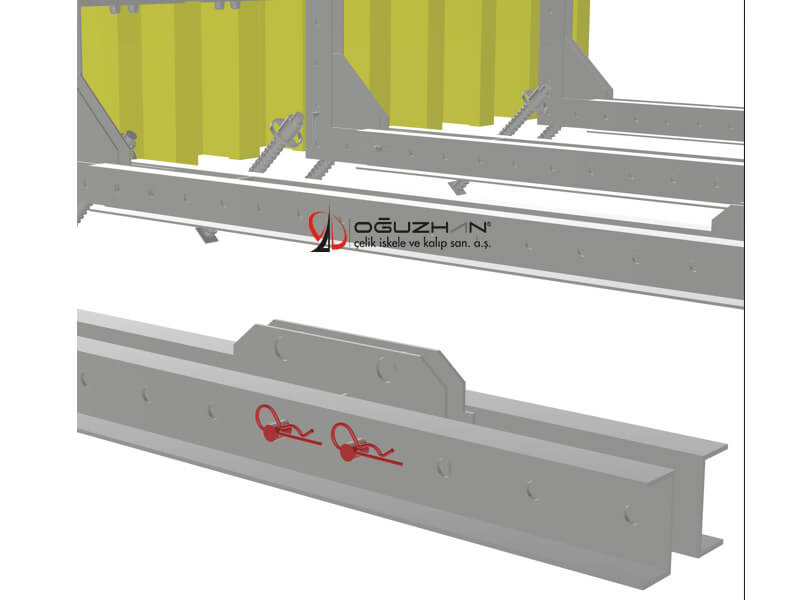

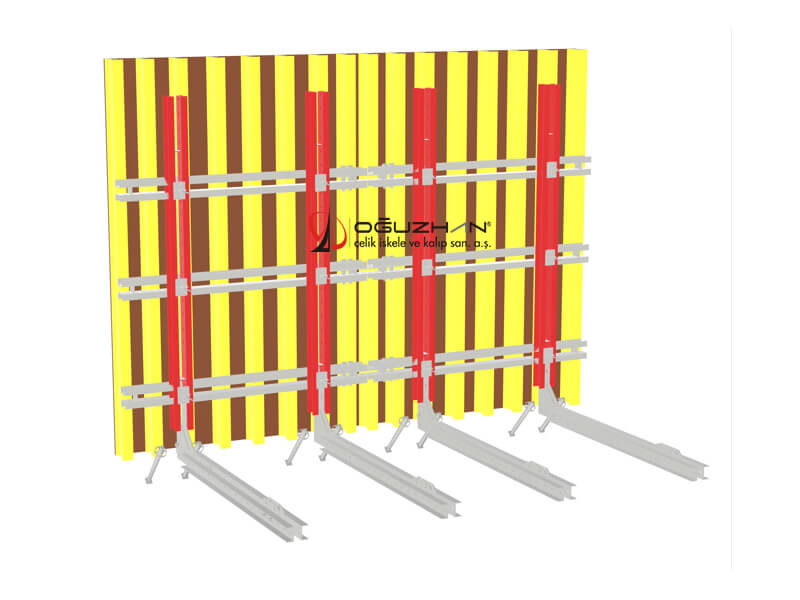

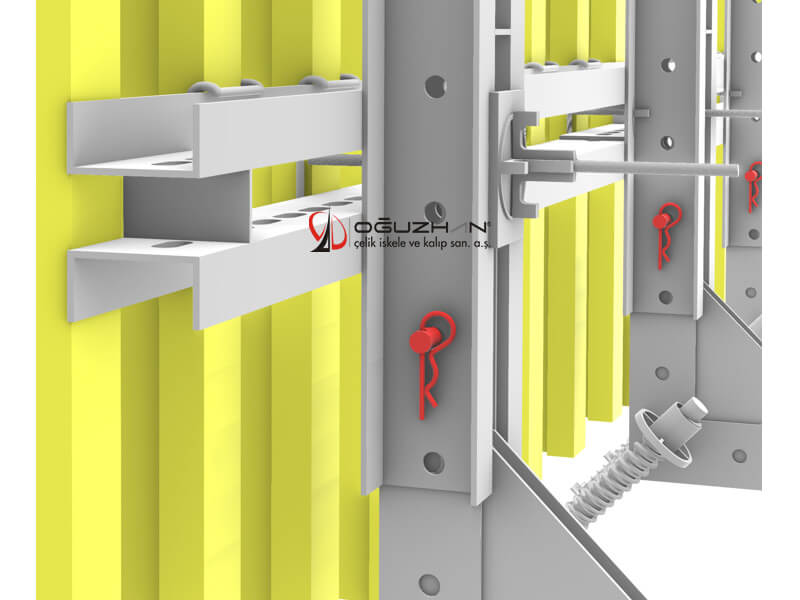

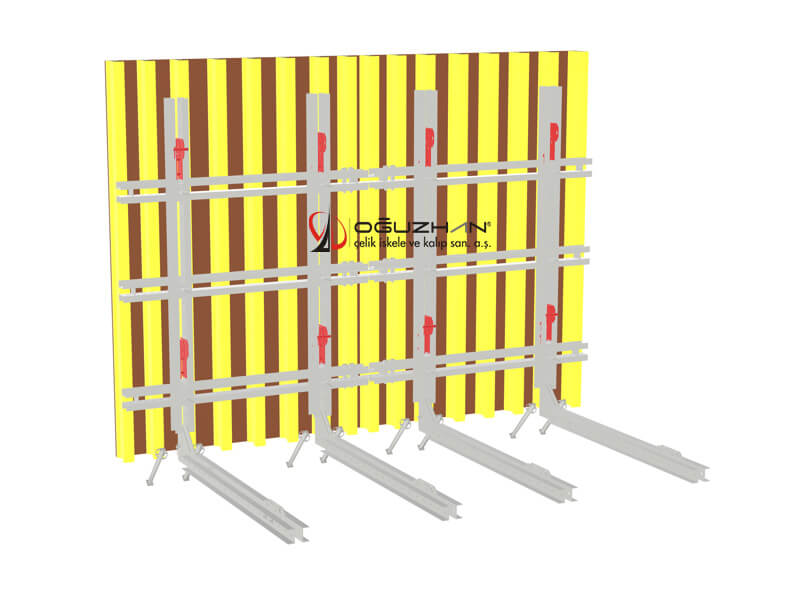

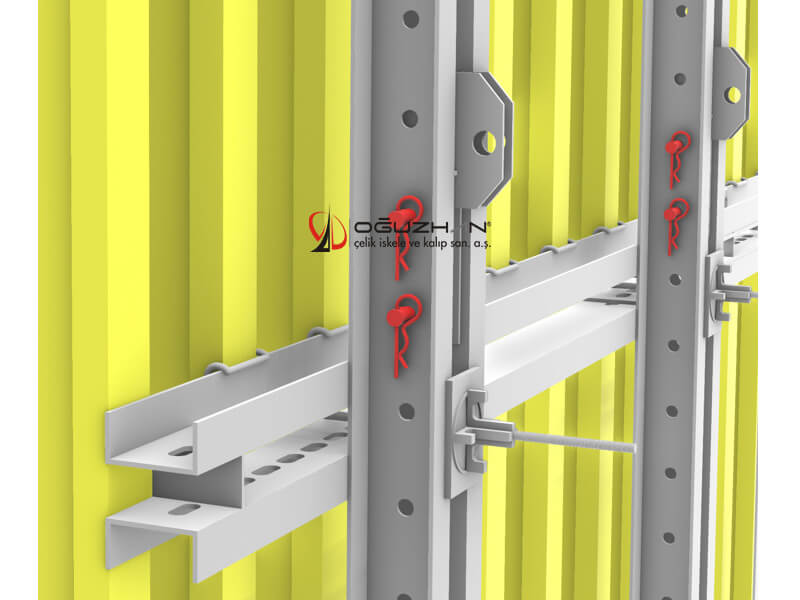

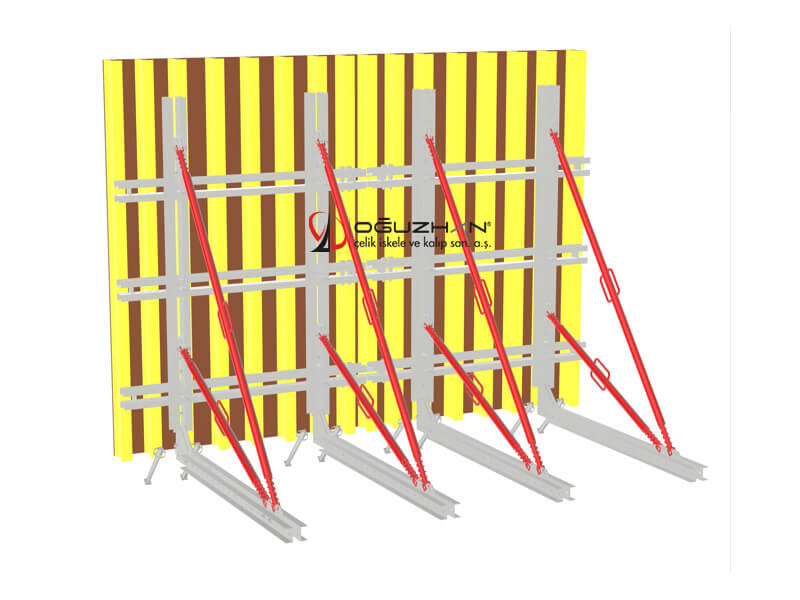

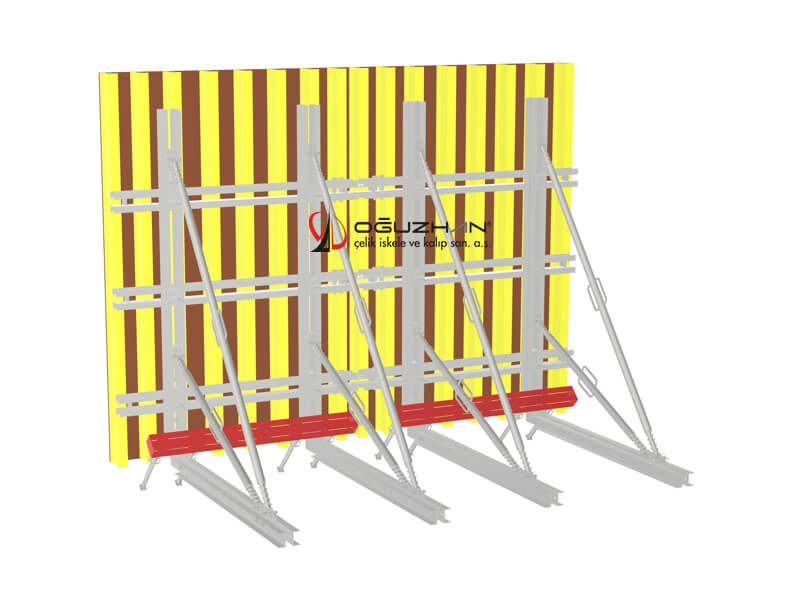

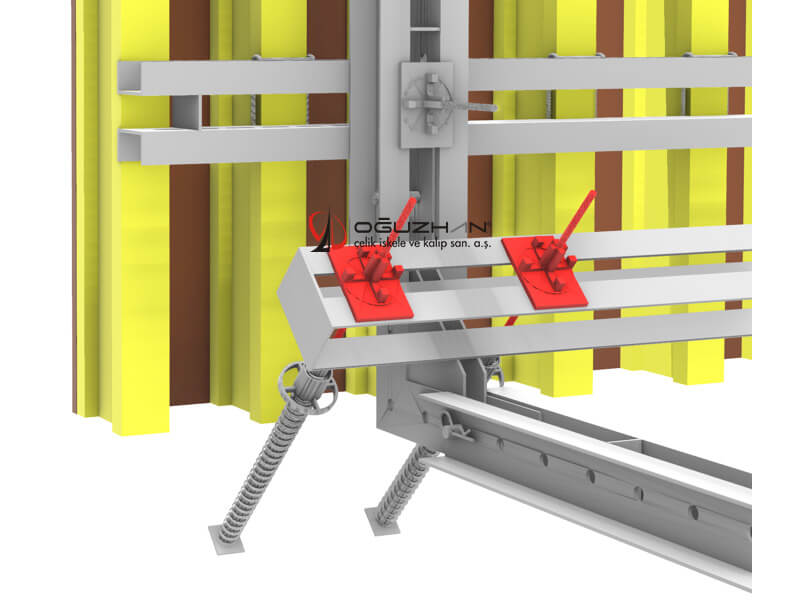

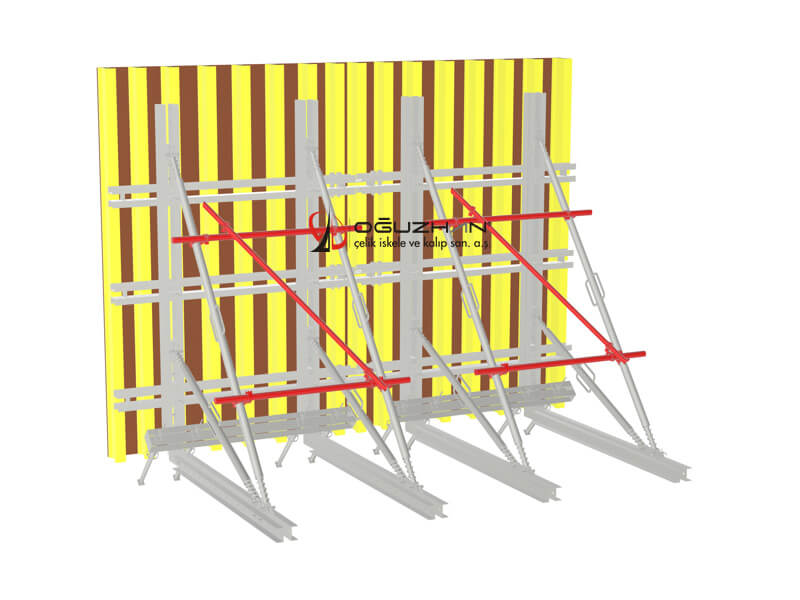

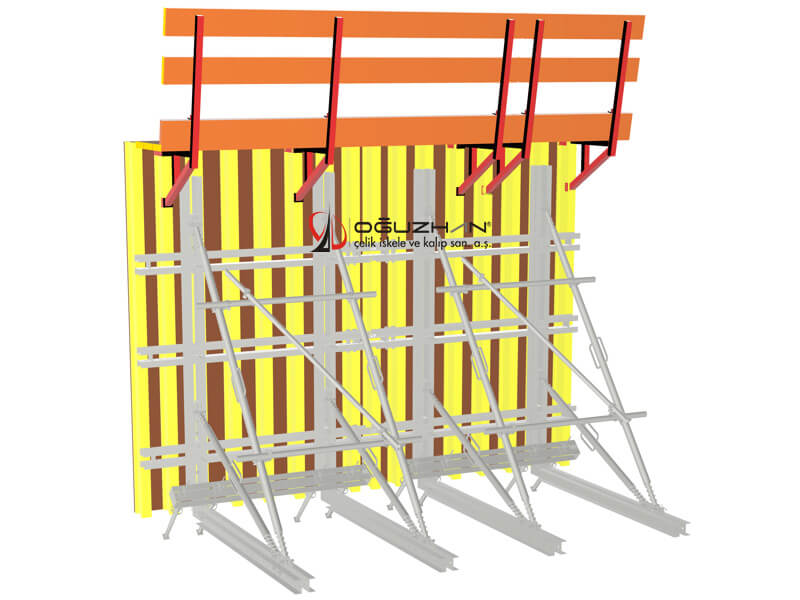

In Single-Sided Wall Formwork: H20 beams reinforced against load transfer, Plywood Surface Layer for long mold life, combined NPU Belt Systems for safe use of the system and Support Strut parts that are resistant to all forces that may come from the system are used together.

Single Face Curtain Formwork System: It consists of Plywood Layer, H20 Wooden Beams, NPU Belts (Vertical, Horizontal, Anchor Belt), Belt Joining Parts, Formwork Anchor Elements, Compression Parts, Support Struts, Crane Handle and Formwork Accessories.

Permanent anchors are used in the concrete for the single-surface formwork system to resist the concrete pressure and to fix the system to the ground.

If it is desired to be used as a formwork system without being disassembled, it is necessary to use a crane during installation or transportation as it is a very heavy system.

Single Sided Curtain Formwork Materials, as OĞUZHAN® brand, comply with TSE EN ISO 3834-2 Quality Requirements Standard for Melting Metallic Materials. The pipes and profiles used in its production are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard.

annotation

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |