GENERAL FEATURES OF STEEL SURFACE COLUMN SCREEN MOLD:

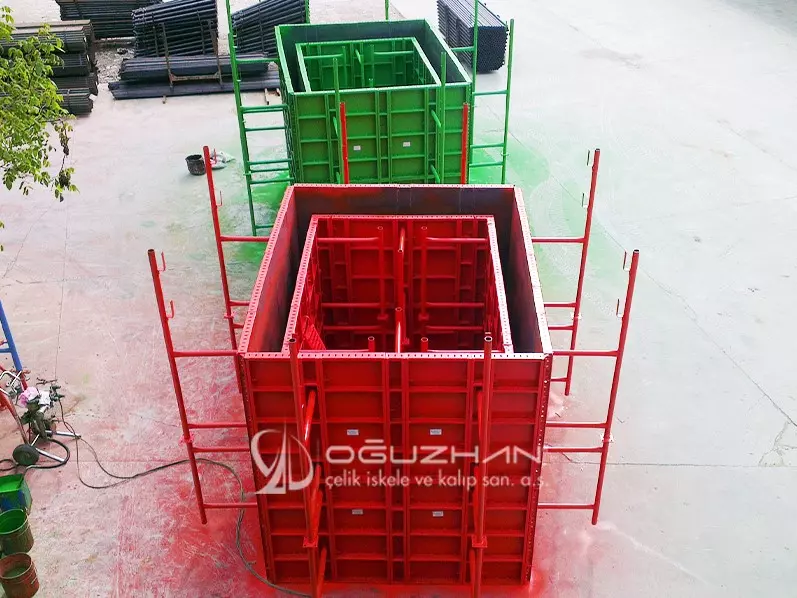

Steel Surface Formwork system is a Formworksystem that is formed by placing Steel metal panels produced in standard sizes on top of each other or side by side and connecting them. It is one of the preferred systems in studies such as column formwork, curtain formwork, circular formwork. Steel metal Formworksystem: It is also known with different names such as "Wedge Mold", "Steel Mold", "Steel Panel Mold" or "Soldier Support Mold".

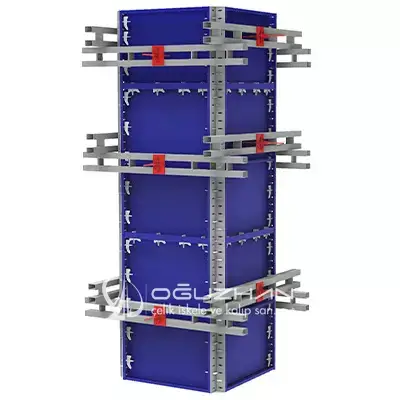

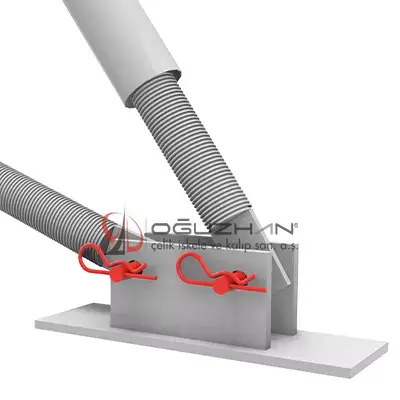

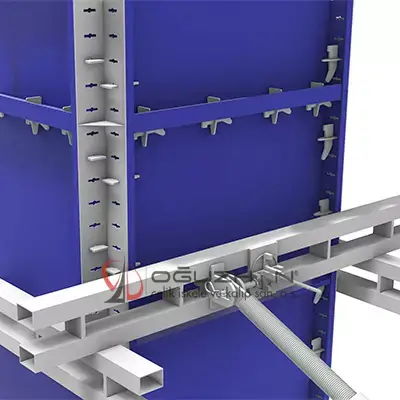

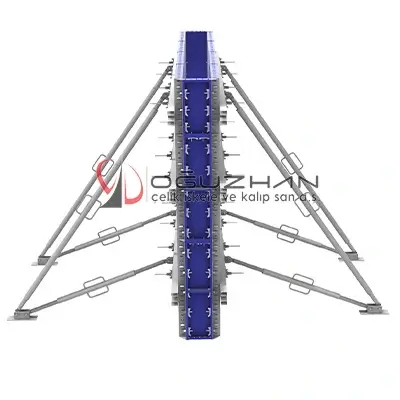

Formwork System: It consists of Steel metal surface formwork panels, fasteners and support elements. Steel metal panels are produced according to standard width/length dimensions. From fasteners, OC corner boards and wedges (Male/Female); Support elements also consist of formwork support belts and struts.

Steel Surface Formwork System: It consists of Steel Metal Molding Panels, Steel Molding Corner Panels (Inner - External Corner), OC Corner Panel, Support Belt (Blue band), Fasteners (Wedges), Strut Elements, Tieroot Compression Elements and Accessories.

Formwork panels can also be specially designed at the desired width and height. In standard sized panels: Surface Steel is made of 2,5mm, Belt Steel is made of 3,0mm Steel. Depending on the high concrete pressure, the surface Steel and belt Steel dimensions increase up to 4.0mm or 5.0mm thickness.

The size variety of the panels in the formwork system is high, the materials are not heavy, they can be installed in a short time. The materials are suitable for continuous use. There is no need to use a crane during installation or transportation.

Formwork Materials are produced under the brand name of OĞUZHAN® in accordance with TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials.

annotation

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |