Ring-Lock Scaffolding

It is a system that can be used in all kinds of working environments such as architectural structures, industrial structures, port works, ship maintenance and repair works, aircraft maintenance and repair works, engineering structures (bridges, culverts, etc.), power plants, factories.

Ring Lock Scaffolds ; They are systems that are practical in the installation-disassembly stages while being used, have the same combination of materials with each other, are generally produced in standard sizes and are resistant to deformation in the construction site environments.

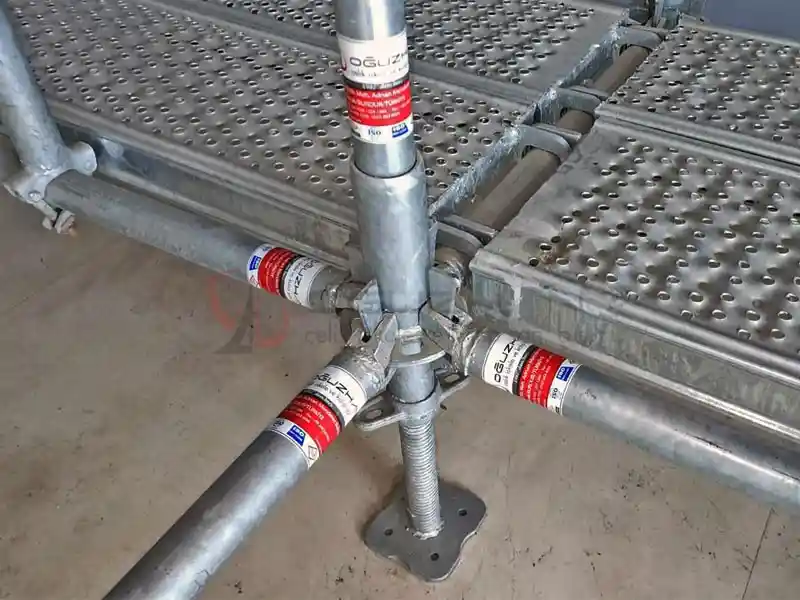

Connection in Ring Lock Scaffolding; It is formed by placing the connection part called "Flange" located at certain intervals on the vertical elements and the "Dovetail" mechanism located in the horizontal elements of the head to the connection point.

Flanges are manufactured from 8.0mm sheet metal. It is welded to the pipe by using gas metal arc welding at 50cm and 100cm intervals by means of a welding robot.

Our Ring Lock Scaffolding Materials are produced under the brand name of OĞUZHAN® in accordance with TS EN 12810 Standard for Facade Scaffolds Consisting of Pre-built Components and TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials.

The pipes used in the production of Ring Lock (flanged) Scaffolding are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard. Afterwards, the scaffolding elements were subjected to Durability, Loading, Deflection and Sphere Throwing tests according to TSE 12810-2 and TSE 12811-1 Standards.

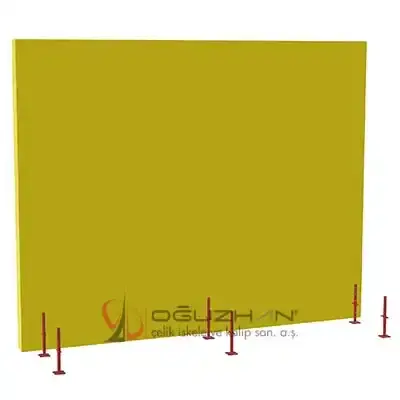

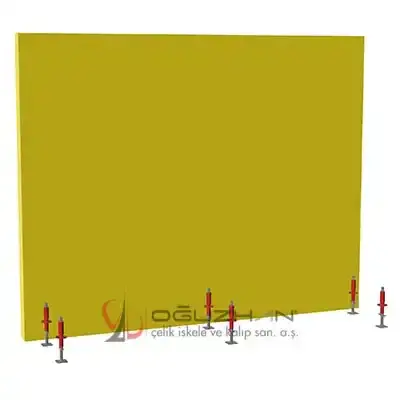

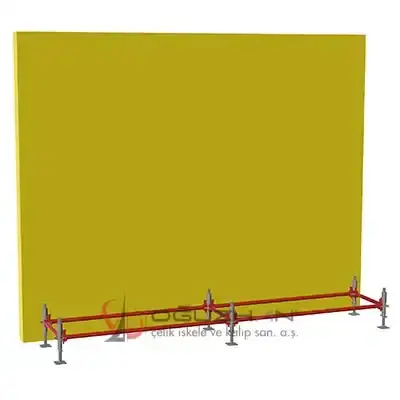

• Ring (Flanged) Scaffolding; It consists of Lower Adjustment Spindle, Starter Leg, Vertical Element, Horizontal Element, Cross Member, Walking Platform (Sheet Plank), Heel (Shin Rail), Platform with Ladder, Overhang Console and Accessories.

• In the ring (flanged) scaffolding system; Manufactured from pipes conforming to TSE EN 10219-2 Standard with lower adjustment shaft 38.0/4.00mm, Vertical members 48.3/3.00mm, Horizontal members 48.3/2.50mm, Cross members 48.3/3.00mm. is being done.

• All elements on the scaffolding system have been subjected to Durability, Loading and Deflection tests according to TSE 12810-2 and TSE 12811-1 Standards. Platforms were tested by throwing a 100 kg Sphere from a height of 2.50 m.

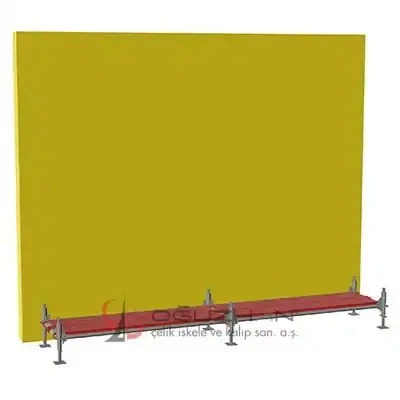

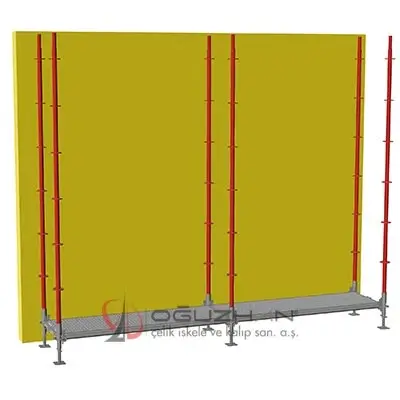

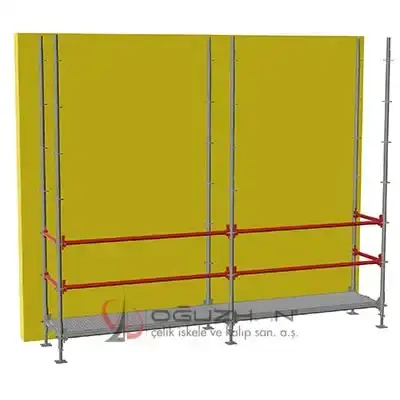

• Installation: Lower adjustment shafts are adjusted, Starting feet are placed, Bottom horizontal elements are added, Vertical elements are placed, All horizontal elements are added, Cross elements are added, Metal platforms are placed, Ladder platform is placed, Heels are placed, respectively for each 2.0 mt height these processes are repeated, a wall connection is made for security purposes.

• Vertical elements consist of flanges made of 8.00mm sheet metal and 48.3/3.00mm pipe, which are joined by welding at 50cm or 100cm intervals. Vertical Elements are 0.50mt, 1.00mt, 1.50mt, 2.00mt, 2.50mt and 3.00mt.

• Horizontal elements are formed by the dovetail mechanism that provides the connection with the scaffolding elements and by welding 48,3/2,50mm steel pipes to each other. They act as guardrails for the scaffolding system, increasing the safety of the scaffolding. It can be produced in 0.35mt, 0.50mt, 0.70mt, 1.00mt, 1.20mt, 1.50mt, 1.80mt, 2.00mt, 2.50mt, 3.00mt sizes.

• Platforms create working areas on the scaffold. They consist of 1.50mm Sheet and Head parts. After the rolled sheet is shaped with a Rollform Machine, it is joined with the head parts by means of gas metal arc welding. Finally, it is taken to the galvanization process. Generally, their width is between 25-35cm; their lengths can be 0.70mt, 1.00mt, 1.20mt, 1.50mt, 1.80mt, 2.00mt, 2.50mt, 3.00mt.

• Platforms with stairs are used on the scaffolding between floors. On its frame made of profile iron, there is a platform surface made of sheet metal such as the head, hooks, ladder part and walking platform. They can be produced in two different types depending on the dimensions of the scaffolding, with cover, with plank or with a landing. Their lengths are adjusted in accordance with standard dimensions.

• Scallops and heels are both names given to the same material. They are the elements used to prevent the material from falling over the scaffolding platforms. It is formed by forming 1.5mm galvanized coil sheets with a rollform machine. Their height is at least 15 cm, their length is between 300cm, 250cm, 200cm, 150cm, 120cm, 100cm, 70cm, 50cm. It is suitable for use on any platform.

• Overhang Consoles create additional workspaces to optimize working conditions on the scaffold. It is manufactured from 48,3/2,50mm pipes. They form protrusions by connecting the flange parts of the vertical elements. Consoles; It can be produced in 0.35mt, 0.50mt, 0.70mt, 0.75mt, 1.00mt sizes.

• Wall fasteners are used to fix the scaffolding system and provide stability. They provide security between the wall and the scaffold, thanks to their mechanisms consisting of 48.3/3.00mm pipe, hook and rod parts.

• Accessories are among the materials used in the scaffolding system, which increase the safety and ease of work flow. Connection pipe, Clamp systems, Intermediate cover grates etc. can be cited as examples.

• In the part of the required standards and legal regulations in scaffolding systems;

TS EN12810-1 Facade Scaffolding Systems Consisting of Pre-built Components (Part 1: Product Properties),

TS EN 12810-2 Facade Scaffolding Systems Consisting of Pre-built Components (Part 2: Special Structural Design Methods),

TS EN 12811-1 Temporary Work Equipment (Part 1: Scaffolding - Performance Requirements and General Design),

TS EN 12811-2 Temporary Work Equipment (Part 2: Material Information),

TS EN 12811-3 Temporary Work Equipment (Part 3: Loading Tests) Standards are discussed.

annotation

Advantages of Wedge Flange Type scaffolding;

Vertical transport system is lighter and more practical as it is not in the form of a frame but in the form of a tube.

During transportation, vertical and horizontal pipes do not occupy much volume.

Since it is not in the form of a frame in cases of being thrown to the ground from a height, there is no square defect.

More robust horizontal and cross pipes are used.

At the same time, it can be considered as a load scaffolding under the formwork by selecting the appropriate head.

Since 300 cm long walking platforms are used, a longer façade can be closed at once.

Flanged Facade Scaffolding Systems are also known by different names in our country; Wedge scaffolding, Wolf mouth Scaffolding, Spider Type Scaffolding (as it can be installed in all directions like spider web), Secure Scaffolding, TSE certified Scaffolding…

There are some curious questions about flanged scaffolding from inside and outside the sector;

What does flanged scaffolding mean? How many kg is flanged scaffolding? What is the Flanged Scaffolding Price? How much is the pier? What is heel plate? How many cm should the heel plate be? How much is the second hand (2.hand) Wedge Flanged Scaffolding price?

We try to explain everything that is curious on our product and blog pages. You can contact us for more.

Wedge Flanged Scaffolding Prices;

We cannot share flanged scaffolding prices on the website. Due to many factors, there may be an instant decrease and increase in flanged scaffold prices. In order to avoid any inconvenience, we request you to learn the current flanged scaffolding prices directly from our factory. You can find all the necessary information on our contact page.

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |