GENERAL FEATURES OF H20 WOODEN BEAM INDUSTRIAL COLUMN SCREEN MOLD:

The Industrial Column Curtain system is one of the most durable systems against the weight of concrete among the formwork systems. Industrial System; It is also known with different names such as "NPU Mold", "SRC Mold", "Belted Mold" or "H20 Mold".

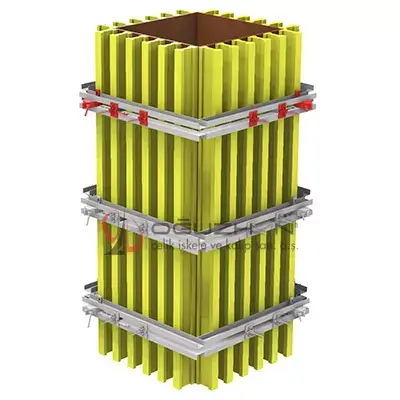

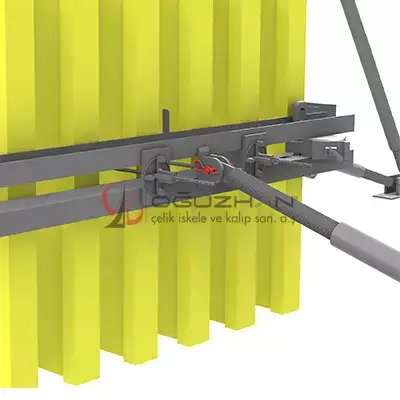

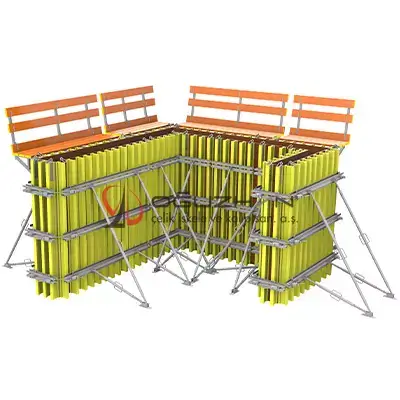

Industrial System: Reinforced H20 beams against load transfer, Plywood surface layer for long mold life and iron components that are resistant to lateral forces that may come from the system are used together. The variety of materials in the industrial formwork system is high, the project can be designed according to the desired size.

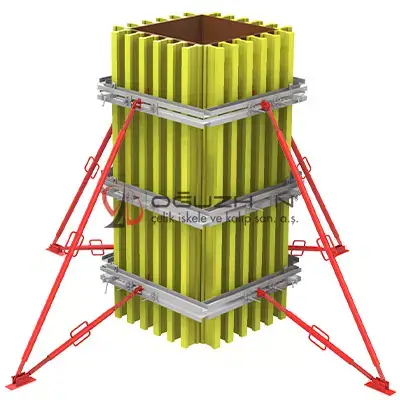

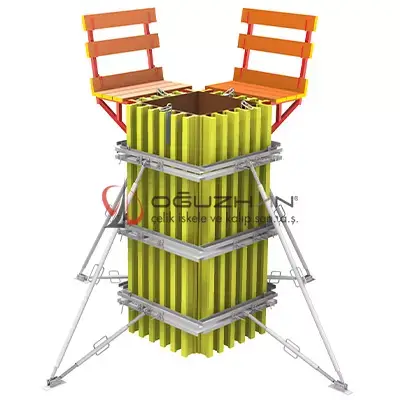

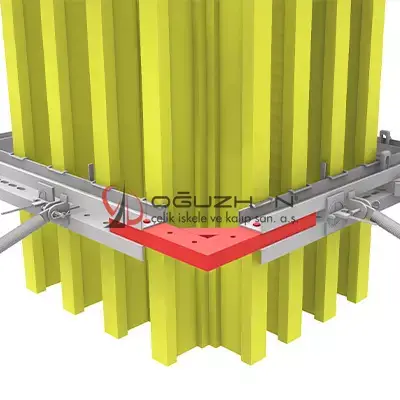

Industrial Formwork System: It consists of Plywood Layer, Reinforced H20 Wooden Beams, NPU Belts (Curtain Belt, Inner Corner Belt, Outer Corner Belt etc.), Joining Parts, Compression Parts, Support Struts, Crane Handle and Formwork Accessories.

Panels of desired width and height can be designed with industrial materials. Anos can be added side by side or on top of each other. Since the material size variety is high, the formwork system can be created in a short time with practical solutions. It is a system that can be used continuously, has a long life, and has a low material loss rate.

If it is desired to be used as a system without being disassembled, it is a heavy formwork system. A crane is required during installation or transport. Since it can be transported directly without being disassembled, a great deal of labor and time savings are achieved.

Industrial Molding Materials are produced under the brand name of OĞUZHAN® in accordance with TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials. The pipes and profiles used in its production are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard.

annotation

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |