SAFE SCAFFOLDING

SAFE SCAFFOLDING

What is Safety Scaffolding?

Safety scaffolding means scaffolding with TS EN 12810-1 certificate issued by TSE. Safe scaffolding means scaffolding in the most superior position in terms of occupational safety. Safe scaffolding means scaffolding with the most resistant hot dip galvanised coating against corrosion in the external environment.

What is the Purpose of Safety Scaffolding?

Short answer Work safety. The purpose of the safety scaffolding is to prevent work accidents caused by falling from height every year. It is to reach European standards that we have lagged behind for years in terms of occupational safety. Statistics from the American Occupational Health and Safety Administration show that 85% of people who fall while working above 3.4 metres lose their lives. Reducing these rates is the purpose of safe scaffolding.

Which type (kind) of scaffolding is safe scaffolding?

Safe scaffolding is not a term that refers to only one type of scaffolding. Safety scaffolding generally refers to all types of scaffolding that meet TS EN 12810-1 standards.

What is the most common type (type) of safety scaffolding?

This expression is generally used for exterior scaffolding systems. The most common types of exterior safety scaffolding used in our country; Wedge Flanged Type scaffolding and H Type Scaffolding. These two systems are not superior to each other in terms of safety because both systems are TSE certified. One of the two systems is preferred according to usage habits. These two systems have their own advantages and disadvantages.

Which type of safety scaffolding is more expensive?

Due to design differences, the Wedge Flanged Safety Scaffolding System is slightly more expensive than the H Type Safety Scaffolding System.

What is Galvanised Safety Scaffolding?

In fact, all safety scaffolding systems are galvanised. Instead of paint, it refers to the coating of safety scaffolding systems with hot-dip galvanised. In fact, there should not be a term such as non-galvanised safety scaffolding or painted safety scaffolding. Because one of the most striking requirements of TS EN 12810-1 certificate is hot dip galvanised coating against corrosion.

Fully safe scaffolding has now become a well-known and sought-after product all over Turkey.

There is a lot of curiosity about this subject. In order to examine all the questions one by one in detail, TS EN 12810-1.. and TS EN 12811-1.. standards must be examined.

However, in this article, we aimed to give a rough idea about Fully safe scaffolding without going into too much detail. After filtering all the standards, we examine the main lines of the safe scaffolding.

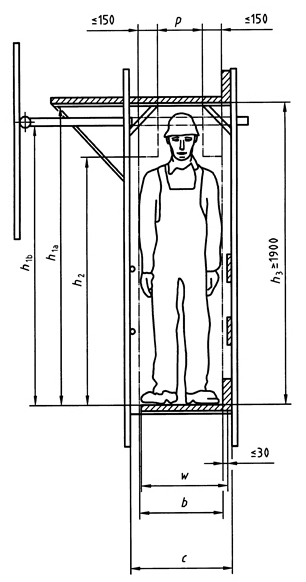

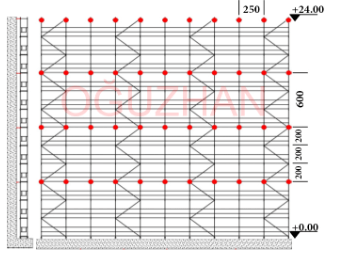

The following visual safety scaffolding standards are used to clarify the main dimensions based on. Details about the dimensions mentioned in this image are below.

Safe Scaffold Dimensions Remarks

b : The free walking section must be at least 500 mm and (c - 250 mm) whichever is greater

c : Clear distance between uprights

h1a, h1b : Net head distance between tie members or transverse interconnects and working area, respectively

h2 : Net shoulder height

h3 : Net head height between working areas

p : The net width in the head height section must be at least 300 mm and (c - 450 mm) whichever is greater.

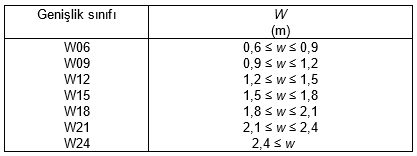

w : Width classes for workspaces

The generally preferred width class in Turkey for safe scaffolding systems is W06. In other words, the width of the sheet metal planks used as a walking platform should not be less than 60 cm, and should not be more than 90 cm, if 2 pieces are used side by side.

If a width over 90 cm is desired, W09 and above classes should be used.

As it is understood from here, since the width of 2 planks coming together cannot be less than 60 cm in total, the width of a plank to be used is min. It should be 30 cm. As Oğuzhan pier, we produce 32 cm wide planks.

The generally preferred width class in Turkey for safe scaffolding systems is W06. In other words, the width of the sheet metal planks used as a walking platform should not be less than 60 cm, and should not be more than 90 cm, if 2 pieces are used side by side.

If a width over 90 cm is desired, W09 and above classes should be used.

As it is understood from here, since the width of 2 planks coming together cannot be less than 60 cm in total, the width of a plank to be used is min. It should be 30 cm. As Oğuzhan pier, we produce 32 cm wide planks.

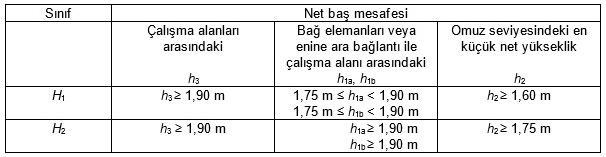

Safe Pier Head distance classes

The standard minimum headroom height for a worker working on a Full safe Scaffolding has been determined as 190 cm.

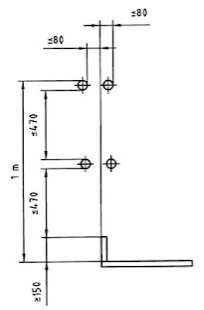

safe Scaffolding Side Protection ( Railing and Heel )

In order to prevent a worker working on Safety Scaffolding walking platforms from falling backwards, 2 rows of railing horizontal elements should be used.

Their minimum dimensions should be 47 cm from the places shown in the figure on the right. The upper distance of the side rails over the walking platform should be 1m.

Heel elements should be used to prevent the feet of the workers working on the safe Scaffold from slipping backwards from the walking platform and to prevent small materials from falling. These should start from the sheet plank level and be at a minimum height of 15 cm.

Safe Scaffolding Lower Adjustment Shafts (Base Plates)

The base plate of the base plates to be used in the safe (Security) Scaffolding is min. It should be in the form of 12.5 cm x 12.5 cm.

It can be produced from embossed or non-embossed flat sheet. During the certification process, it is tested and approved in TSE laboratories.

safe Scaffolding Wall Fasteners

It is one of the most vital parts of the Fully Safe scaffolding system. The number of pieces to be used emerges as a result of static calculations. If a protective net or tarpaulin will be placed on the outer surface of the scaffold, the frequency of wall connection increases.

The configuration and instruction manual contains information on the number of wall fasteners that should be used.

It is shown as an example as red dots in the figure below.

Safety Scaffold Cross Fasteners

Cross member must be used in safe scaffolding systems. Cross members are numbered according to the situation that will occur in static calculations. In our company's products, this situation is min. 1 full (with cross), 2 empty (without diagonal) and max. It comes out as one full (crossed) and 4 empty (uncrossed).

In the figure below, you can see the cross table explaining 1 full, 2 empty situations.

safe Scaffolding Galvanized Coating

All of the products that make up the safety scaffolding systems should be galvanized. Painted products are excluded from this standard (TS EN 12810-1).

Safe Scaffolding Tests and Experiments

-Platform Experiments:

1. Drop Test

2. Single Load Test;

a) Stamina

b) Deflection

3. Uniformly Distributed Load Test

4. Partial field load Test

-Ladder Experiments:

1. Single Load Test

2. Uniformly Distributed Load Test

-Deflection Tests:

1.Side Protection Deflection Test;

a) Vertical Downward Loading Test

b) Horizontal Loading Test

c) Upward Vertical Loading Test

2. Heel Board Deflection Test

Our Products

Corporate

Products

© Copyrights Reserved 2026