Plywood

Plywood

Plywood with 20 Articles,

Information : A research firm has published a report on the largest plywood manufacturers and companies in the world. According to this report, the global plywood market size reached USD 45.5 billion in 2022 and is expected to reach USD 62.3 billion by 2028. (IMARC)

Preface

What is Plywood?

The term "plywood" comes from the English language and is used to describe layered wood products. The term is a combination of two English words:

a-"Ply" refers to layers or layers. Plywood is produced by combining various layers of wood boards together, so the term "ply" emphasises the number or structure of layers.

b- The word "wood" represents wood material in general. Plywood is a building material created by gluing and pressing wooden boards.

Therefore, the word "plywood" is a term describing a building material consisting of wooden boards assembled in layers. And PLYWOOD as a product is a versatile building material created by cross-layering layers of wood fibres. This material has a durable and stable structure thanks to the crossing of wood fibres. Plywood is a widely used material in construction, furniture production, packaging and many other industries.

PLYWOOD GUIDE

| Contents; |

1- Short History of Plywood;

2- How is Plywood Made? What are the Production Processes?

3- Plywood Types and Usage Areas

4- Film Coated and Film Uncoated Plywoods

5- Lubrication of Concrete Moulds with Plywood Surface

6- What are the factors you should pay attention to when buying plywood?

7- What are the factors you should pay attention to when using plywood?

8- Advantages of Plywood

9- Disadvantages of Plywood

10- Plywood Thickness Dimensions

11- General Information

12- How many times is plywood used?

13- Plywood Mounting recommendations

14- Plywood Prices

15- Plywood Formwork Applications

16- Domestic Plywood and Imported Plywood: Similarities, Differences and Reasons for Preference

17- Which names are plywoods called in our country?

18- Why is the word "plywood" searched a lot on the internet;

19- What can be done to have information about plywood:

20- Plywood Certificates - Quality Certificates:

| We have handled the plywood issue in all details, we have compiled and compiled for you; |

1- Short History of Plywood;

The history of plywood dates back to ancient Egypt. Ancient Egyptians obtained a plywood-like material by gluing wood layers of different colours and pressing them with sandbags. The modern use of plywood started in the 19th century. In 1797, Samuel Bentham applied for patents for several machines to produce veneer. In these applications, he put forward the idea of gluing thin layers of wood to form a thicker piece. This idea was later developed by Immanuel Nobel and the rotary lathe machine was invented. Plywood has become a revolutionary material in architecture, design, aircraft and shipbuilding in the 20th century.

2- How is Plywood Made? What are the Production Processes?

Plywood Production Processes: Transformation of Wood

Plywood is an important building material for construction, furniture and many industrial applications. The production process of plywood goes through a series of carefully followed steps. oguzhaniskele.com

a- Log Selection: Plywood production process starts with a quality start. A good log is selected from a tree tree suitable for the desired plywood type. This log is called "peeler". The peeler should be flat and have a large diameter, because many layers will be produced from this log.

b- Layer Creation: A large knife is used for processing thin layers. It is important to place the tree horizontally under the blade to achieve better results. The blade is continuously pressed and many layers are cut into pieces.

c- Heat Exposure: The layers are then exposed to heat to remove the water content. Ensure that the sheets are well dried before proceeding to the next step.

d- Gluing: After drying, the sheets are glued together, preserving the structure of the different types of plywood. Care is taken to achieve the best result in this step. The gluing process is done carefully. Urea formaldehyde and phenol formaldehyde are used for gluing. Furmecyclox is also used to provide fungus resistance.

e- Baking, Pressing: Glued plywood main boards are subjected to baking and pressing at the required temperature and pressure. Minimum temperature is 140 degrees centigrade and pressure is 1.9 MegaPascal.

f- Finishing, Sizing: Finally, the defects of the produced plywood sheets are removed. Holes, pits or incomplete edges are corrected. Also, resizing and shaping operations are carried out at this stage.

Plywood production is a complex process and requires attention and care to achieve quality results. This process is important for the durability and usefulness of plywood and should be followed carefully.

3- Plywood Types and Usage Areas

Plywood is used as a basic building material for construction, furniture making and many industrial applications. There are different types of plywood, each of which has its own characteristics and usage areas;

a- Softwood Plywood: Softwood plywood is usually made from wood species such as spruce, pine and red pine. It has a hard structure that can be used effectively in concrete moulds, construction strips and building construction.

Areas of Use: Construction works, industrial applications, ventilation panels, floor, wall and roof coverings in building construction, construction of machine and vehicle parts, packaging, fence construction around the area.

b- Hardwood Plywood: Hardwood plywood is obtained from hardwoods and is known for its hardness, durability and resistance quality on its surface. It can be used to carry heavy loads.

Areas of Use: Floor coverings of houses, used to provide structural structure to walls, widely used in places that require abrasion resistance.

Special Areas of Use: Hard plywood obtained from trees such as birch is used for special applications such as turbine blades for wind machines.

Some types of hard plywood coated with phenolic resin are used for panels in concrete formwork systems.

It is used in areas such as floors, roofs and side walls of transport containers.

Used in scaffolding constructions.

c- Tropical Plywood (Tropical Wood Plywood): Tropical plywood is produced with a mixture of different tree species of tropical regions. This type of plywood was previously only collected from Asia, but now it is also available from Africa and America.

Areas of Use: Construction, concrete formwork systems, building structures, floor coverings, floors of transport containers, furniture making.

d- Aircraft Plywood: Aircraft plywood is made from trees such as mahogany, spruce and birch. This type of plywood is recognised for its strength and is heat resistant.

Uses: During World War II, it was used as aircraft plywood to prevent air attack. Also some British aircraft use this material. Parts of aircraft such as wing surface, fuselage sections and wing beams are made of this type of plywood.

e- Decorative Plywood (Fancy Plywood): Decorative plywood is usually made from wood species such as ash, oak, red oak, birch, maple, mahogany and Philippine mahogany, also known as seraya. This type of plywood is generally used in furniture and interior decoration.

Uses: Fancy plywood is widely used for furniture, cabinets, doors, home decoration.

f- Flexible Plywood: Flexible plywood is used to make flexible furniture or structures. It is made of Baltic birch wood in the construction of such furniture.

Usage Areas: Types of hats and furniture made using flexible plywood, such as the chimney pipe hat during the reign of Queen Victoria.

g- Marine Plywood: Marine plywood is a type of plywood that can be used in humid, damp and wet environments. It can also be used in humid conditions for a long time. The layers of marine plywood have a small enough core spacing to trap water inside the wood, which does not allow water to enter the core spacing. It is also fungus resistant.

Areas of Use: Shipbuilding, watercraft construction, vehicle and bench construction for restaurants and parks exposed to open spaces.

Each type of plywood is specially designed for specific applications and needs. Therefore, understanding the properties and usage areas of plywood types is important to choose the right material for the right project.

4- Film Coated and Film Uncoated Plywoods

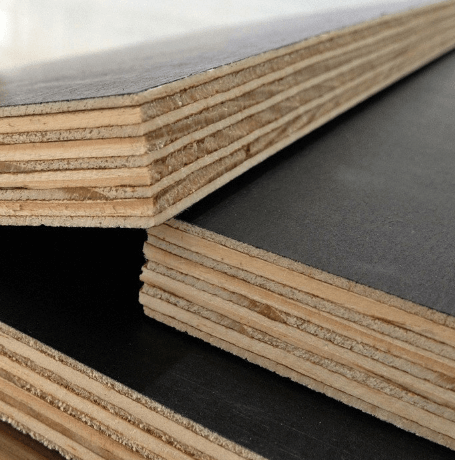

a- Film Coated Plywood:

Filmed plywoods are produced by applying phenolic film on their outer surfaces. This film is usually brown or black phenolic film. Film coated plywoods provide a glossy surface and are preferred on surfaces that will not be plastered. This type of plywood allows you to get gross concrete and is frequently used in the construction industry.

b- Plywood without film coating:

Filmless plywoods are produced without phenolic film application on their outer surfaces. In this way, their outer surfaces remain in natural wood appearance. Filmless plywoods are preferred on surfaces to be plastered and offer a non-glossy surface. This type of plywood is used in many areas such as furniture, packaging, lorry trailers and decoration.

As a result, filmed plywood is ideal for obtaining glossy exposed concrete on non-plastered surfaces, while filmless plywood is preferred for plastered surfaces and offers a natural wood appearance. In the construction industry, both types of plywood are used according to different needs.

5- Lubrication of Concrete Moulds with Plywood Surface

Concrete moulds are an essential part of construction projects and the maintenance of the moulds affects the outcome of the project. The surfaces of concrete moulds must be smooth and this is achieved with mould oil. Mould oil prevents concrete from sticking to the moulds, allows easy removal and increases the smoothness of the concrete surface. Besides mould lubricant, correct granulometry and an effective vibration process, together with concrete quality, are critical factors to achieve a smooth surface. However, careful preparation of the concrete contact surfaces of concrete moulds and correct removal of the mould are also extremely important.

The choice of mould lubricant depends on the type of mould used and the requirements of the project. The moulding oil forms a film layer between the mould and the concrete and this layer must be resistant to mechanical movements, abrasion and shear stresses.

Mould oils used in concrete are generally divided into two main groups: mineral oils, synthetic oils and mineral based oils. These oils are enriched with various chemical additives and made suitable for the needs of the moulds. These oils are mould release agents.

When selecting mould oil, it is important to consider the requirements of the project and the intended use. Clean and proper application of the moulding oil also improves the quality of the results.

6- What are the factors you should pay attention to when buying plywood?

a- Physical Structure and Quality: The physical structure of plywood sheets is a critical factor determining the durability of the product. The boards should be cut properly, the thickness should be consistent, the layers should be smooth and the surface should be smooth. You should also be careful about the angle and miter of the boards during your inspections.

b- Moisture Content: The moisture content of plywood sheets is important. Ideally, the moisture content should be around 10%. Plywood with high moisture content can cause problems in use and outdoors.

c- Quality and Combination of Layers: The inner and outer layers of the plywood (plywood) board must be smooth and these layers must be firmly connected to each other. Otherwise, the product may undergo rapid deformation and its service life may be shortened. You can guess about the internal structure from the gaps on the edges of the boards.

d- Glue Material: The glue material that joins the layers of plywood boards greatly affects the durability of the product. It may be difficult to see the quality of the glue with the naked eye, but you can get some information from the glue colour when you cut a small piece and separate the layers. Quality glue produces a more robust and durable Plywood.

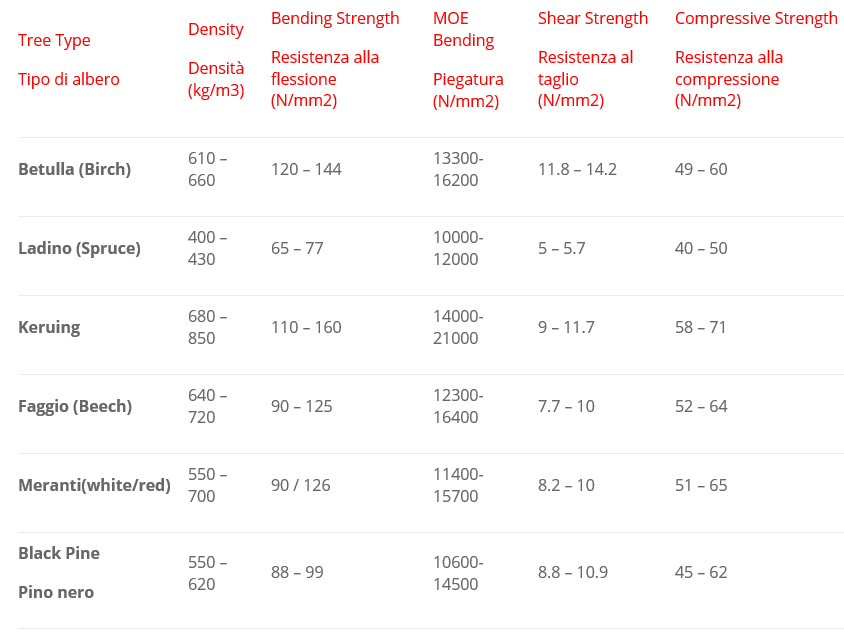

e- Wood Type and Layer Thinness: The type of wood used and the thinness of the layers affect the carrying capacity of the Plywood (plywood) board. Thin-layer products generally have a higher load carrying capacity and are more elastic. Also, the choice of wood species is important. Some trees perform better in Plywood, while others may deform more quickly.

f- Selection according to intended use: You should choose the type of plywood according to the place and purpose of use. Plywoods with different quality classes and properties may be required for construction projects.

When buying plywood, it is important to pay attention to the physical properties, quality, intended use and suitability for environmental conditions. A quality and correctly selected Plywood plays a critical role in the success of your projects and helps you achieve long-lasting results.

7- What are the factors you should pay attention to when using plywood?

There are a number of important issues to be considered when using plywood. You can use plywod materials in the best way by considering these issues:

a- Choose Plywood Type Correctly: You should correctly determine the type of plywood according to the work to be used and the number of uses. You should also use the necessary apparatus by calculating the support intervals. Choosing the type and size of plywood suitable for the project increases structural durability.

b- Attention During Assembly: Plywood sheets should be carefully nailed during assembly and dismantled when necessary, and you should use a small number of nails or screws. You should be careful not to embed such fasteners into the plywood surface. You should also isolate nail or screw holes with paint using a drill in film-coated materials. You can increase durability by using suitable accessories and corner protectors at the joints.

c- Preventive Maintenance: You should regularly apply protective oil or coating before and after the use of plywood. This increases the durability and life of the material. During stacking, you should take care not to accumulate stones or other materials in between.

d- Cutting Operations: You should cut the plywood with a high speed saw in an open area or by wearing appropriate protective masks. The cut areas should then be insulated with protective paint or coating. Also, you should not expose plywood to direct sunlight for a long time, as this may affect the quality of the material.

e- Careful Handling and Use: Plywood sheets should not be dropped, especially vertically, and should not be subjected to severe impacts. This prevents the boards from cracking or deforming.

f- Special Use Cases: If you are going to use plywood in places that will be exposed to water and heat, you should prefer marine glued plywood. This type of plywood increases water and temperature resistance.

g- Pay Attention to Application Conditions: You should pay attention to the conditions of use during plywood application. Correct installation techniques, conformity to the sheet dimensions and the use of corner/corner profiles increase the efficiency of the plywood and reduce the loss.

Plywood materials should be carefully selected, installed and maintained correctly. These steps contribute to the success of your projects by increasing the durability of the material.

8- Advantages of Plywood

Plywood is a preferred building material in many construction and furniture applications and offers many advantages. Here are the advantages of plywood:

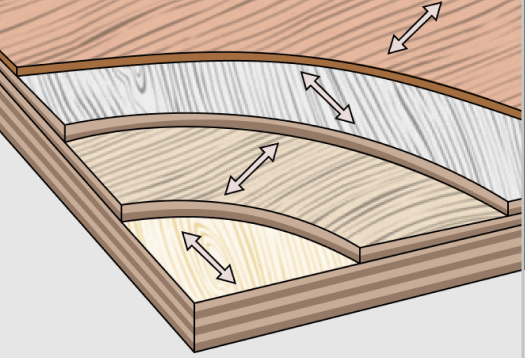

1. Cross Layer Structure: There is a cross layer structure in plywood. This is one of the advantages of plywood. Because:

a- The cross layer helps prevent splitting when you nail the edges.

b- Increases the durability of the material.

c- It binds the wood grains more tightly.

d- Prevents unnecessary expansion and wood shrinkage.

2. Structural Stability: Plywood, its structure is stable, provides stability. In this way:

a- The consistency of the board is maintained in all directions.

b- A uniform structure is obtained and this structure increases strength.

c- Plywood reduces the possibility of bending due to the balanced joining of an odd number of layers.

d- The rigidity of plywood prevents warping and increases the stability of the material.

3. Contribution to Economy: Plywood contributes to the economy. Because:

a- Solid wood is heavy, but furniture made of plywood is easier to transport and lighter.

b- Less weight reduces transport costs.

c- Plywood helps to obtain more products while minimising material waste.

4. Ecological Importance: Plywood has ecological importance. Because:

a- Wood is a renewable resource in nature and trees for plywood production are sustainably grown.

b- During the production of plywood, it is an environmentally friendly option as wood produces minimal waste and energy is saved.

c- Plywood is a recyclable material, which contributes to the conservation of natural resources.

Plywood is an excellent option for many applications with its durability, functionality and environmentally friendly structure. The cross-layer structure increases the strength of the material, while being an economical and environmentally friendly option makes plywood indispensable in the modern construction and furniture industry.

9- Disadvantages of Plywood

Although plywood is a preferred building material for many applications, it also includes some disadvantages;

a- Glue Substances and Health Risks: Gluing agents such as urea and phenol formaldehyde used in plywood production are substances that can be carcinogenic. Therefore, exposure to these substances may carry health risks. It is important to take appropriate protective measures when using plywood.

b- Weaker than Wood: Plywood may be weaker than solid wood in some aspects. Since it does not have the natural durability of wood, it may be more sensitive to external factors.

c- Durability: Plywood is not as durable as solid wood. In the long term, there may be cracks, peeling and wear and tear.

d- Difficult to Process: Plywood can be more difficult to shape or carve than solid wood. It may not be suitable for projects that require fine detailed workmanship.

e- Lighter: Plywood is a lighter material than normal wood. This may be an undesirable feature in some applications, especially where structural strength is required.

f- Susceptibility to Insect Attack: Plywood is not resistant to insect attack in long-term use. If appropriate precautions are not taken, insects can cause damage.

g- Sensitivity to Moisture and Wet Weather: Plywood (except marine plywood) should not be exposed to humid or wet weather conditions for a long time. In such conditions, problems such as swelling, dissolution and decay may occur.

h- Surface Problems if not painted: If the surface of the plywood is not covered with film and is not painted well, it may peel or crust over time. Therefore, attention should be paid to surface protection.

Although plywood is a versatile building material with many advantages, these disadvantages should also be considered. Depending on the characteristics and requirements of each project, the advantages and disadvantages of using plywood should be evaluated.

10- Plywood Thickness Dimensions

Generally accepted as the standard mould size is '2500 mm x 1250 mm'. However, it is also possible to find '3000 mm x 1500 mm', '2440 mm x 1220 mm', '1525 mm x 1525 mm' sizes.

Plywood types can be in thicknesses ranging from 6 mm to 30 mm. The most common plywoods and thicknesses in our country are as follows;

Pine Plywood: 15, 18, 21 mm

India Plywood: 15, 18, 21 mm

Birch Plywood: 15, 18, 21 mm

Malaysian Tropical Plywood: 15, 18, 21 mm

Odek Birch Plywood: 15, 18, 21 mm

Romanian Aspen Plywood: 15, 18 mm

Riga Plywood: 15, 18, 21 mm

Sveza Plywood: 15, 18, 21 mm

Syply Plywood: 15, 18, 21 mm

Upg Birch Plywood: 15, 18, 21 mm

Vietnam Plywood: 15, 18, 21 mm

WISA-Form Beto Plywood: 15, 18, 21 mm

WISA-Form Birch Plywood: 15, 18, 21 mm

11- General Information

12- How many times is plywood used?

Plywood used in construction moulds can be reused a different number of times depending on the duration of use and durability. The quality of plywood is the main factor determining the life of the material. A high quality plywood can have more usage cycles, while a low quality plywood can be reused less often.

The lifetime of plywood can be influenced by the following factors:

a- Material Quality: Good quality plywoods are durable and can be used for a longer period of time. Thicker and stronger plywoods are generally more reusable.

b- Conditions of Use: Plywood may differ depending on how it is used and environmental conditions. For example, frequent exposure of plywood to water or extreme temperature changes can shorten its service life.

c- Maintenance and Cleaning: Regular maintenance and cleaning of plywood can extend its service life. Dirty or damaged plywoods are less reusable.

d- Intended Use: Plywood can be reused for different periods of time depending on the purpose for which it is used. For example, plywood used in reinforced concrete moulds may be subject to more wear and tear and therefore may need to be replaced more frequently.

In general, a good quality plywood can be reused an average of 10 to 20 times or more. (Birch plywood has a high service life. 55-75 mould range (flipping) can be used. Low quality plywoods produced in India can only be used between 5-10 moulds.) However, usage conditions and maintenance measures may affect this period. In order to maintain the service life of the plywood in the best way, regular maintenance should be carried out and instructions for use should be followed.

13- Plywood Installation Recommendations

Plywood assembly is a process that can vary under the influence of various factors. Therefore, it is important to pay attention to the time and place where the installation will be carried out. Especially changes in the humidity levels of the environment can cause fluctuations in the dimensions of plywood panels. There are some important recommendations to minimise these fluctuations and achieve a more durable assembly.

a- Leaving Gaps: Before the plywood panels are placed in the installation area, it is important to leave small gaps between the panels. These gaps help the panels to adapt to humidity changes. Generally, gaps between 1/8 inch and 1/4 inch are preferred.

b- Edge Insulation: Insulating the edges of the plywood panels during assembly contributes to the long life of the panels. Edge insulation is especially important for plywood to be used outdoors or in high humidity areas. If the edges of the plywood panels you have purchased are not already insulated, it is recommended to insulate the edges with acrylic paint or a suitable water repellent product. This will make the panels more resistant to the effects of water and moisture.

c- Suitable Coating: Before the installation of plywood panels, it is recommended to apply a coating suitable for the intended use; mould oil or varnish for concrete moulds. This coating protects the panels against external factors and increases their durability. Especially in exterior facade applications, the use of a coating resistant to UV rays provides long-term protection.

d- Correct Mounting Techniques: When installing plywood panels, it is very important to use the correct assembly techniques. It is important to place the panels properly, use appropriate bolts or screws and follow all necessary steps during assembly. In addition, adding appropriate supports under the panels ensures that the assembly is solid and safe.

As a result, when installing plywood, it is very important to take precautions such as spacing, edge insulation and appropriate coating so that the panels can adapt to size changes. In addition, using the correct installation techniques and properly supporting the panels increases the durability of the assembly and ensures a long-lasting result.

14- Plywood Prices

Plywood prices vary depending on its type, thickness and quality. Local market conditions, supply and demand are also among the factors affecting prices. Quality plywood comes at a higher cost, while thinner and standard types can be more affordable.

If you think whether plywood prices will increase or decrease in the future, it is difficult to predict with certainty what will happen in the future as plywood prices are affected by many factors. Plywood prices can be affected by the following factors:

a- Wood Raw Material Costs: The prices of wood raw materials used for plywood production (for example, wood species used in plywood production) are an important factor affecting plywood prices. Wood raw material prices can vary depending on a number of factors such as supply and demand, forestry policies and climatic conditions.

b- Demand and Supply: Plywood demand varies depending on construction projects, furniture production, packaging industry and other areas of use. High demand and low supply can increase plywood prices.

c- Production Costs: Plywood production process is affected by many factors such as energy costs, labour, technology and efficiency of production facilities. These factors can affect plywood production costs, which can be reflected in prices.

d- Exchange Rates: Since plywood is an international material, exchange rates can also affect prices. Changing exchange rates can affect plywood imports and exports.

e- Regulations and Environmental Factors: Sustainability of wood resources and forestry practices, regulations and environmental factors for plywood production may increase production costs or affect production processes.

We cannot know with certainty how all these factors will interact to predict future plywood prices. Prices may vary regionally and fluctuate over time. It is important to follow market analyses and industry news to predict how plywood prices will change in the future. You should also consider local and international economic developments.

Plywood Price Ranges

Plywood price ranges can vary widely depending on a combination of factors such as Quality, Size and Thickness, Manufacturer and Brand, Market Variables and Additional Costs. Plywood panels specifically designed for mould work can range from $65 to $225 per slab for 2023.

$ 65 <> $ 225

It is important to make the right choice of plywood, taking into account the requirements and budget of your project. Quality and durability can save money in the long run, so instead of choosing the most affordable option, it may make more sense to opt for the plywood that will best suit the needs of your project.

15- Plywood Formwork Applications

Plywood formwork can be used in a wide range of construction. These various applications include:

Apartments and Houses: Plywood formwork is ideal for residential projects. They can be used for moulding concrete slabs, columns and walls, helping to achieve solid and smooth surfaces.

Bridges and Infrastructure Projects: Plywood formworks offer excellent durability and bearing capacity in the creation of large concrete structures. It is a preferred solution for bridges and infrastructure projects.

Industrial Plants: Industrial projects include large structures such as factories and warehouse buildings. Plywood formworks are frequently used in such projects and their durability helps to achieve excellent results.

Plywood formworks are the perfect solution for concrete formworks in the construction industry. They stand out with their ability to provide environmentally friendly, durable and fast assembly. They also contribute to achieving aesthetic results. The flexibility of plywood moulds and their suitability for various applications have a significant impact on the construction industry and are expected to become even more widespread in the future.

When considering concrete formwork, it is important to remember that plywood formwork is a remarkable solution. They offer a sustainable option in terms of both environment and performance and make a significant contribution to the successful completion of construction projects.

16- Domestic Plywood and Imported Plywood: Similarities, Differences and Reasons for Preference

You may be thinking and not finding an answer; Should I use domestic or imported plywood? Why should I use domestic plywood? Why should I use imported plywood? Which plywood should I use? Here are a few ideas to help you;

a- Similarities:

Basic Material: Both domestic and imported plywoods are basically produced by compressing thin layers of wood. By combining these layers together, a durable and strong structure is obtained.

Variety: Both domestic and imported plywoods offer different thickness, size and quality options. This allows you to find the appropriate plywood option for various projects.

Applicability: Both domestic and imported plywoods can be used in many different applications such as construction, furniture making, cladding and packaging.

b- Differences:

Place of Production: A key difference is that domestic plywood is produced in local markets such as Turkey, while imported plywood comes from abroad. This can affect the supply chain and prices.

Cost: Imported plywoods usually have higher price tags because import processes, transport and customs duties lead to additional costs. Domestic plywoods can often be more affordable because they are produced in the local market.

Quality Standards: Imported plywoods usually comply with international quality standards and therefore have a certain level of quality. Domestic plywoods may also have high standards of quality, but standards may vary by country.

c- Reasons for Preference:

Budget: The budget of your project may affect your choice of domestic or imported plywood. If you are working with a more limited budget, domestic plywoods are usually more affordable.

Quality: Depending on the requirements of your project, you may need a certain level of quality. Imported plywoods usually guarantee a certain level of quality.

Sustainability: Domestic plywood can be a more sustainable option because it is produced from local sources and transport costs are lower, which can reduce environmental impact.

In conclusion, when choosing between domestic and imported plywood, you should consider factors such as the needs of your project, budget, quality and sustainability. Both options have certain advantages, and making the right choice can be critical to the success of your project.

17- Which names are plywoods called in our country?

a- According to Import Countries: Russian Plywood, Indonesia Plywood, Brazil Plywood, Malaysia Plywood, Romania Plywood, Vietnam Plywood, India Plywood...

b- According to Brand and Manufacturer Companies: Araujo, Bettega, Cocha, Fankom, Formaplan, Formply, Galeras, Logan, Miraluz, Miforte, Paged, Pinorus, Riga Form, Samling, Smileply, Sveza, Syply, Tekcom, Tulsa, Tyumen, Woodex…

Georgia Pacific LLC, Potlatch Corporation, Weyerhaeuser, Boise Cascade Company, UPM-Kymmene Corporation, Sveza, Metsa Wood, Latvijas Finieris, Austral Plywoods Pty Ltd, Eksons Corporation Bhd…

c- According to the trees it is produced: Birch Plywood, Hardwood Plywood, Pine Plywood, Oak Plywood, Mahogany Plywood...

d- According to local regional pronunciation: Playvut, Pleymut, pleyvut, pileyvut, pleyvud, pleymud... in different regions. However, the prominent local pronunciation is PLEYMUT.

18- Why the word "plywood" is searched a lot on the internet;

a- Material Search: Plywood is a building material created by gluing wood layers. By searching for this term, a person can try to reach information such as the properties, usage areas, prices or sales points of plywood.

b- Research for Project: Plywood can be used for different applications such as wood veneer, furniture making, construction, carpentry or craft projects. Therefore, a person may search to learn about the types and sizes of plywood required for a particular project.

c- Price Comparison: There are different types and grades of plywood, so a person can search to compare prices from different sellers.

d- Plywood Types: Plywood comes in different types, such as water-resistant plywood, plywood. A person may want to find out about a particular type of plywood.

e- Education and Information: A person interested in woodworking or construction may want to learn more about plywood and how to use it.

f- Purchase Intention: If a person is thinking of buying plywood, they may search for this word to find local plywood sellers, online stores or furniture stores.

19- What can be done to have information about plywood:

a- Do Research: You can do research on the internet to get a general understanding about plywood. Check out resources to learn the basics of what plywood is, how it is produced and the different types.

b- Read Books and Articles: To get more detailed information about plywood, you can review written sources such as books, magazine articles or academic studies. Such sources can provide in-depth information about the properties, history, uses and industrial applications of plywood.

c- Get Information from Experts: To gain more insight into plywood, you can contact experts in woodworking, construction or carpentry. They can provide you with practical information on plywood types, quality standards, usage tips and how to use it in projects.

d- Vocational Training: If you would like to gain a more in-depth knowledge of plywood, you may want to consider training in a related trade, such as carpentry or woodworking. Such training can provide hands-on experience on how to cut and process plywood.

e- Consult Local Training Resources: You can contact local educational institutions or carpentry schools that organise courses or seminars on plywood and woodworking. Such trainings can give you practical skills.

f- Experiment and Practise: One of the best learning methods is experimentation and practice. You can learn more about plywood by making small projects using plywood or by improving your woodworking skills.

g- Ask Questions: Ask experts or the woodworking community any questions you have about plywood. Resources such as forums, social media groups or carpentry workshops can help you find answers to your questions.

20- Plywood Certificates - Quality Certificates:

Quality and Sustainability in Wood Products

Plywood is a durable and versatile wood product that is widely used in many areas such as the construction and furniture industries. However, it is important to ensure quality and environmental compliance. In the plywood industry, a number of certification and certification standards have been developed to assess and verify the quality and environmental impact of wood products. oguzhaniskele.com Here are some of these certificates:

a- Attestation_E1: This is a European standard that limits and regulates formaldehyde emission levels. The E1 certificate confirms that the formaldehyde emission of plywood products is within safety limits.

b- CARB_MR (California Air Resources Board - Made with Recycled Wood): Developed by the California Air Resources Board, CARB_MR certification regulates formaldehyde emissions from plywood products and encourages the use of recycled wood.

c- CARB_ULEF (Ultra-Low Emitting Formaldehyde): This certification verifies that plywood products have ultra-low formaldehyde emission levels and aims to improve indoor air quality.

d- CARB ATCM § 93120.3(d) (ULEF): Regulated by the California Air Resources Board, this standard identifies and certifies Ultra-Low Emitting Formaldehyde (ULEF) plywood products.

e- EPA-EXT-LN: This certificate issued by the US Environmental Protection Agency (EPA) specifies the low formaldehyde emission levels of plywood products.

f- BFU-100 Certificate: The BFU-100 certificate is a certificate issued by the German Plywood Association and confirms the quality and durability of plywood products.

g- EN 13986-2004: This European standard specifies the general technical characteristics of wood-based board materials and verifies the conformity of plywood products.

h- FSC® (Forest Stewardship Council): FSC certification verifies that plywood products comply with sustainable forestry and environmental compliance standards.

i- ISO 9001: ISO 9001 specifies the quality management systems of plywood products and promotes continuous improvement.

j- CE (Conformité Européenne): The CE marking indicates that plywood products used in Europe comply with certain health, safety and performance standards.

k- M1 Emission: The M1 emission certificate indicates that plywood products have low emissions that will not harm indoor air quality.

m- MED (Marine Equipment Directive): Materials such as plywood may need to have a MED certificate in order to be used in the marine industry. This certificate indicates that the product complies with maritime standards.

n- REACTION TO FIRE: Used to determine and classify the degree of fire resistance for building materials such as plywood. Fire resistance classifications show how the material behaves during fire and how long it can withstand fire.

o- CLASSIFICATION REPORT: Classification of materials such as plywood according to the places where they are used is done through these reports. For example, the properties of a building material such as fire resistance or suitability for the maritime industry can be specified in these reports.

p- PEFC (Programme for the Endorsement of Forest Certification forest certification): If a plywood product has a PEFC certificate, it shows that the raw materials of this product are sustainably managed and produced in an environmentally responsible manner.

r- TS EN 12369-2: "Plywood - Terms and Classification - Part 2: Plywood Coated with Wood Surface Coating" is a Turkish Standard. The main purpose of this standard is to determine the definitions and classifications of plywood materials coated with wood surface coating. TS EN 12369-2 describes the various properties and structures of plywood materials so that the use, trade and applications of these materials can be carried out in accordance with the standards.

These certificates are important to verify the quality, environmental suitability and durability of plywood products. When buying or selling plywood, paying attention to the relevant documents helps you maintain quality while promoting the use of sustainable and reliable materials.

Conclusion,

Plywood is a versatile building material and is used in many areas from the construction industry to furniture production. Given the types of plywood, their advantages and disadvantages, it is important to choose the one that best suits the needs of your project. You should also consider your budget and quality requirements by comparing between domestic and imported plywoods.

Our Products

Corporate

Products

© Copyrights Reserved 2026