Why can the cast ledger head break during construction site use?

Why can the cast ledger head break during construction site use?

Why can the cast ledger end of the scaffold break on the construction site?

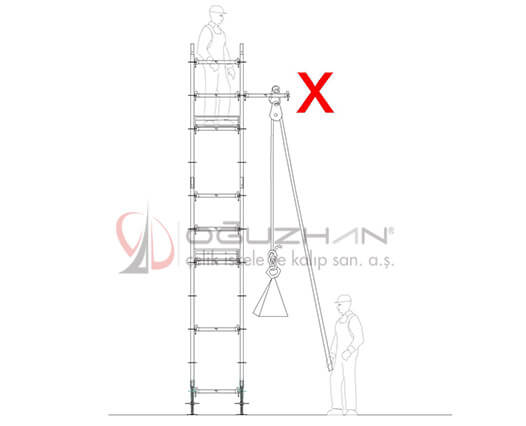

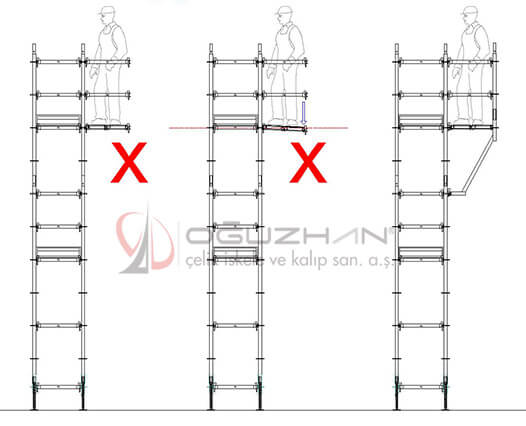

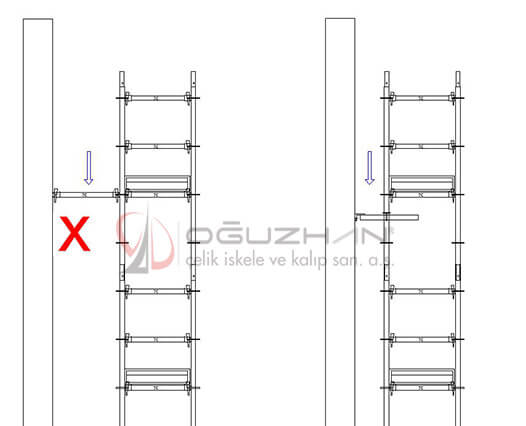

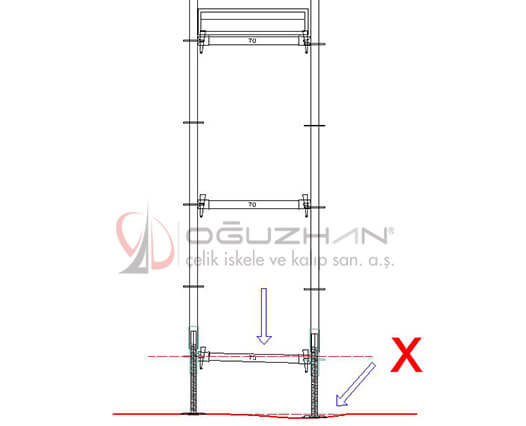

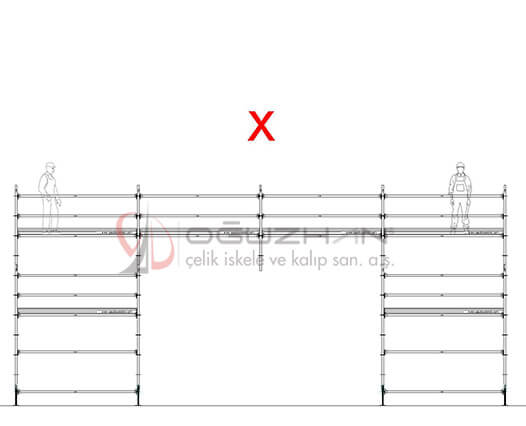

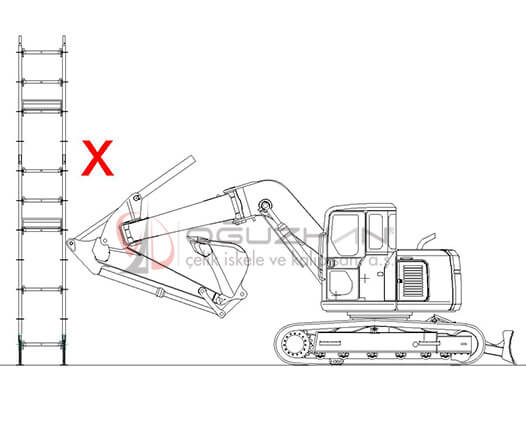

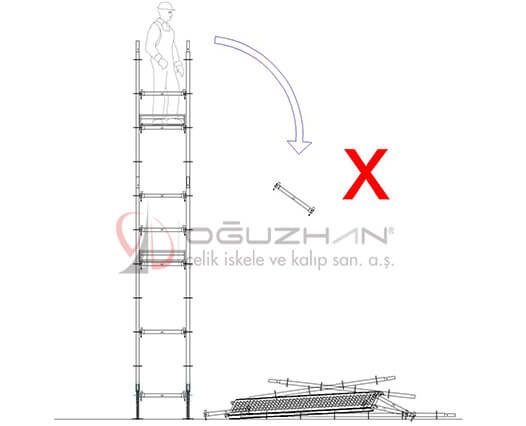

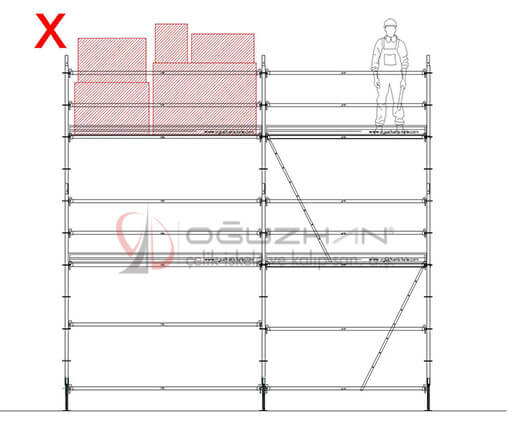

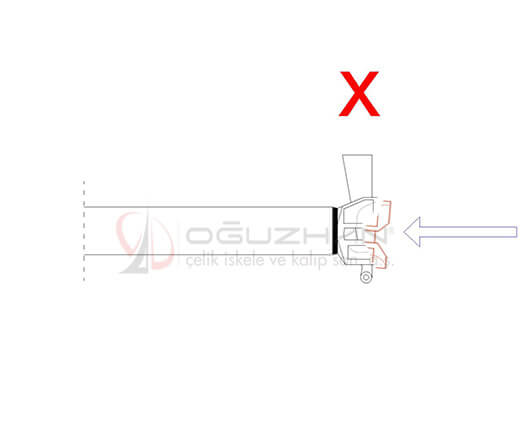

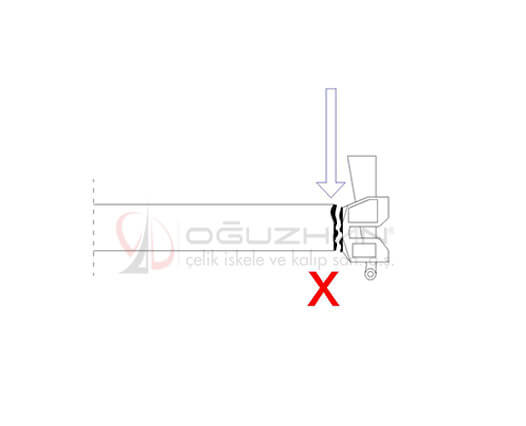

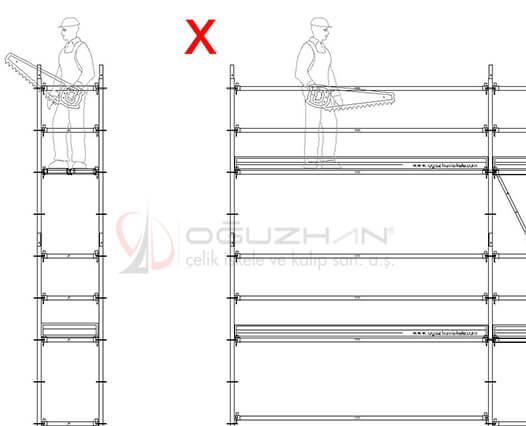

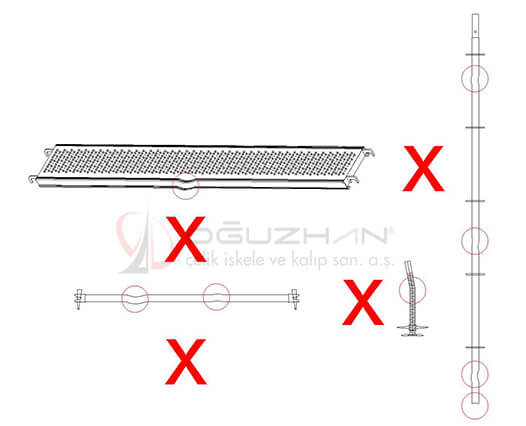

In which faulty uses can cast ledger end break?

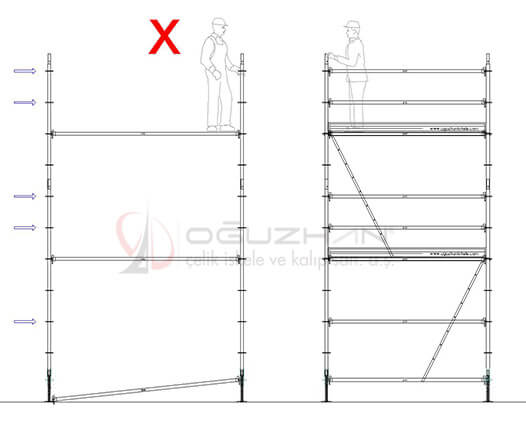

Mistakes made on the construction site during the application phase of flanged wedge scaffolding systems? Deformed scaffolds due to mistakes on the construction site;

As OĞUZHAN ÇELİK İSKELE VE KALIP SAN. A.Ş., we present below our article, which we have collected and originally written according to the information and experience from the field and all the curious questions (S.S.S.) about Flanged Scaffolding systems;

|

|

|

|

|

|

|

|

|

|

|

|

|

* Do not forget that even if you have just bought the scaffolding system and used it once, if you have made big mistakes in that one use and damaged the system elements. In the second use, you are always likely to experience work accidents caused by your scaffolding system. Therefore, you must first trust the scaffolding systems. For this reason, Oguzhan Steel Scaffolding and Formwork Co. has been providing trust and service to its customers for almost 40 years. After having a scaffolding system you can trust, you should install, use, dismantle and maintain the scaffolding system with a team you can trust. |

This article has been an article that we, as Oğuzhan Çelik Scaffolding and Formwork Co. It has been an article in which we have compiled the mistakes made in scaffolding systems at construction sites. Please do not copy without permission. We hope you have found answers to the questions in your mind. If this article was useful to you, you can contribute to us by sharing the link to our page on your social media accounts. Thank you.

Our Products

Corporate

Products

© Copyrights Reserved 2026