scaffolding periodical control, risk analysis report, static project

scaffolding periodical control, risk analysis report, static project

Scaffolding Systems Periodic Control / Inspection, Risk Assessment / Analysis, Installation, Use and Dismantling Plans, Procedures, Static Reports and more...

Among all the issues related to scaffolding systems, the most confusing issue is periodic checks, installation / use / dismantling plans, usage report, conformity report, risk analyses, static reports, etc.

When the risk is great, there are many procedures. At the beginning of 2022, in the documents published by the ÇSGB (for 2020), the rate of deaths caused by falling from height in fatal occupational accidents in the construction sector is 37.5%.

As OĞUZHAN ÇELİK İSKELE VE KALIP SAN. A.Ş., we present below our article, which we have collected and originally written according to the information from the field and the relevant legislation, about the whole process of scaffolding systems and all the curious questions (faq);

'THE ADVENTURE OF THE SCAFFOLD'

Contents;

A- PRODUCTION STAGE

1- TSE Certified Safety Scaffolding Production

a- Manufacture of scaffolding

b- Scaffolding tests and experiments

c- Static Calculation of Scaffolding

d- Preparation of product manual

e- TSE certification

B- MUNICIPAL CONSTRUCTION LICENCE STAGE

1- Pier Project

a- What is a scaffolding project?

b- Who prepares the scaffolding project?

c- How is the scaffolding project prepared and according to what?

d- Sample scaffolding project?

C- CONSTRUCTION SITE PHASE

1- Scaffolding erection, use and dismantling plan and report

a- What is scaffolding erection, use and dismantling plan?

b- Who prepares the scaffolding erection, use and dismantling plan?

c- What is scaffolding erection, use and dismantling report?

d- Scaffolding erection, use and dismantling instructions procedure?

2- Scaffolding Trainings Documents and Certificates

a- Scaffolding Inspection Training / Scaffolding Controller Training

b- Scaffolding Supervisor Training

c- Scaffolding erection staff training?

3- Scaffolding Control Form

a- What is a scaffolding control form?

b- How often and when should scaffolding be checked?

c- Who prepares the scaffolding control form?

d- Example of scaffolding control form

4- Scaffolding Static Calculation Report

a- What is scaffolding static calculation?

b- Who makes the static calculation of scaffolding?

c- scaffolding static calculation example?

5- Scaffolding Compliance Report

a- What is scaffolding suitability report?

6- Risk Assessment / Risk Analysis for Scaffolding

a- What is risk assessment / risk analysis?

b- Who performs the risk assessment/ risk analysis?

c- Is there a penalty for not preparing a risk assessment / risk analysis?

d- Example of scaffolding risk assessment? Scaffolding risk analysis example?

7- Scaffolding Periodic Control / Scaffolding Periodic Inspection

a- What is scaffolding periodic control?

b- What is the scaffolding periodic control regulation, how can I access it?

c- Who performs scaffolding periodic control?

d- How long is the scaffolding periodic control period?

e- Scaffolding periodic control report?

f- How is scaffolding periodic control done?

g- Sample scaffolding periodic control form / content?

d- Sample scaffolding project?

D- RECYCLING PHASE

1- What happens to the scrap piers?

A- PRODUCTION STAGE

1- TSE Certified Safety Scaffolding Production

a- Manufacture of scaffolding

Scaffolding systems are manufactured from raw materials supplied in accordance with TSE standards in Oğuzhan Scaffolding production facility in accordance with TS EN 12810-1 standards. Products are hot dip galvanised and packaged.

b- Scaffolding tests and experiments

The samples determined by TSE from the scaffolding parts completed in Oğuzhan scaffolding are sent to an accredited institution for testing by TSE, and the conformity reports received are submitted to TSE. In addition, Durability, Loading, Deflection and Sphere Throwing tests and other measurements are carried out according to TSE 12810-2 and TSE 12811-1 Standards of scaffolding elements under the supervision of TSE in Oğuzhan production facility and reported by TSE authorities.

c- Static Calculation of Scaffolding

Scaffolding static calculation is made according to the standard installation for 24,5m height required by TSE and submitted to TSE. These calculations are made separately according to the scaffolding coating types as open, semi-open (mesh covered) and closed (tarpaulin covered) and anchor points are determined according to the coating conditions.

d- Preparation of product manual

A product manual is prepared in accordance with the criteria required by TSE. In the product manual; All features of the scaffolding parts, installation of the scaffolding system, anchorage points determined according to static calculation, scaffolding coating alternatives (open, semi-open, closed) and other requested details are included. Oguzhan product manual is presented to our customers who purchase our safety scaffolding systems.

e- TSE certification

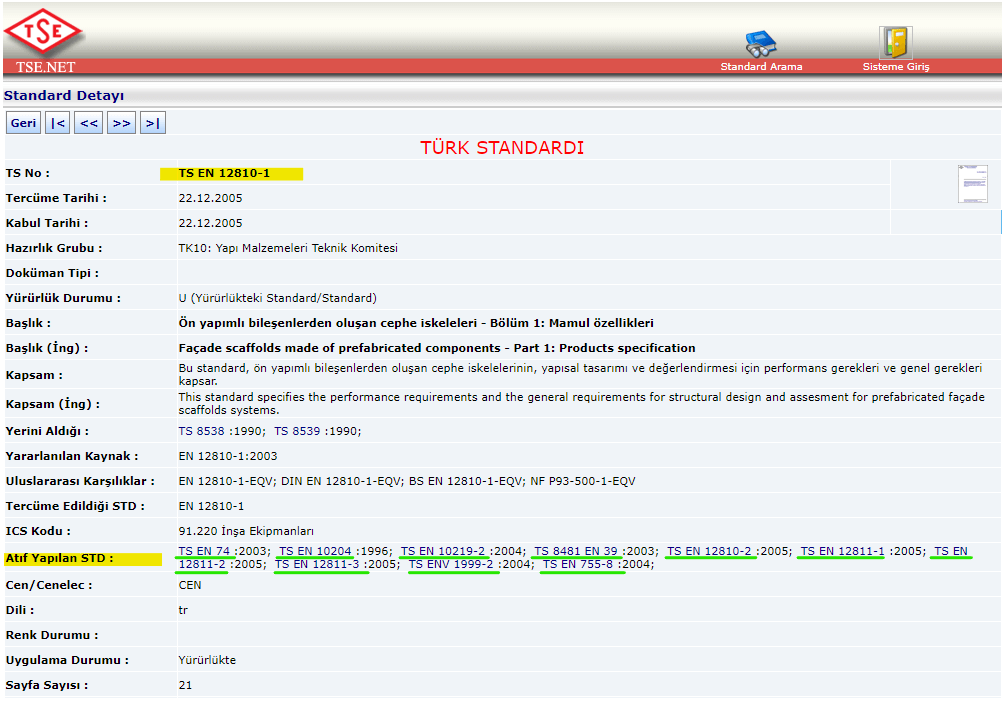

As a result of all these processes, TSE completes the necessary examinations and the certification process takes place. The main document for exterior scaffolding systems is TS EN 12810-1 certificate and is available in Oğuzhan Scaffolding.

It is also useful to explain this because it is asked a lot;

TSE also does not perform TS EN 12811 certification because this document is within the scope of the main standard TS EN 12810-1. In other words, TS EN 12811-1 certification is not made to companies that do not fulfil the requirements of TS EN 12810-1. For more detailed information, you can contact TSE.

B- MUNICIPAL CONSTRUCTION LICENCE STAGE

1- Pier Project

a- What is scaffolding project?

Scaffolding project means that the scaffolding systems to be used in the constructions are designed separately for each construction with the help of package software, the installation designs are made from the simulator and the installation is statically calculated and the suitability is reported.

b- Who prepares the scaffolding project?

Civil engineers or static project engineers prepare the scaffolding project. In order to be a static project engineer, it is necessary to graduate from the Civil Engineering programme of universities.

c- How is the scaffolding project prepared and according to what?

Scaffolding project design and calculations should be based on the standards given by TSE for scaffolding systems. In addition to the TS EN 12810-1 standard, the standards referred to are the following as shown in the image above;

TS EN 74 :2003; TS EN 10204 :1996; TS EN 10219-2 :2004; TS 8481 EN 39 :2003; TS EN 12810-2 :2005; TS EN 12811-1 :2005; TS EN 12811-2 :2005; TS EN 12811-3 :2005; TS ENV 1999-2 :2004; TS EN 755-8 :2004;

d- Sample pier project?

Each municipality has determined its own criteria and has prepared a sample pier project related to the pier project or determined the conditions. Instead of searching for a random sample project on the internet, you can obtain it free of charge from the municipality you are affiliated with in the fastest and most accurate way.

C- CONSTRUCTION SITE PHASE

1- Scaffolding erection, use and dismantling plan and report

a- What is scaffolding erection, use and dismantling plan?

As it can be understood from the title, it is an explanatory plan that you can explain to someone who does not know how to set up the scaffolding, how to use the scaffolding and how to dismantle the scaffolding when the work is done.

b- What should be in the scaffolding erection, use and dismantling plan?

First of all, there should be matters specified in the user manual regarding the installation, use and dismantling of the scaffolding.

Information about the structure and environment where the scaffold will be installed (pedestrian and vehicle traffic, excavation works, distances to high voltage lines, ground conditions, condition of the structure or building to which it is connected, etc.).

Measures taken to prevent material fall and human fall during working at height.

The order in which installation and dismantling operations should be carried out (User Manual)

Issues to be considered during stacking, transporting, lifting and lowering of scaffolding materials (falling, tipping of materials, ergonomics, etc.)

Issues related to anchorage (properties of anchorage materials, anchorage points on the structure, etc.)

The issues related to ensuring the order and cleanliness of the working environment.

Issues related to health and safety signs.

Other issues to be considered specific to the work performed.

(ÇSGB General Directorate of Occupational Health and Safety -Safe Scaffolding Project (GİP) - Safe Working Methods in the Installation and Dismantling Stages of Facade Scaffolding 2014) www.oguzhaniskele.com

c- Who prepares the scaffolding erection, use and dismantling plan?

4.3.2. Depending on the complexity of the selected scaffold, the erection, use and dismantling plan should be prepared by a civil engineer, construction technician or high technician in construction works and by a shipbuilding engineer in shipbuilding and dismantling works. This plan may be in the form of a standard form containing detailed information about the scaffold. (Annex-2 of the Regulation on Health and Safety in the Use of Work Equipment)

d- What is scaffolding erection, use and dismantling report?

If desired, a report can be prepared from the processes carried out during the preparation of the scaffolding erection, use and dismantling plan. In addition, if a scaffolding erection, use and dismantling plan is prepared separately for scaffolds of different types and characteristics at different points of the construction site, all these can be kept in one place as a scaffolding erection, use and dismantling report.

e- Scaffolding erection, use and dismantling instructions procedure?

It is prepared to ensure the safe use of scaffolds to be used in construction works. Here you can find an example of scaffolding erection, use and dismantling instructions. Each construction site can prepare a specific instruction.

2- Scaffolding Trainings Documents and Certificates

Scaffolding trainings have sub-headings such as scaffolding erection/dismantling trainings, scaffolding inspection (supervision) trainings, scaffolding supervisor trainings. Different trainings should be given to the people who will install the scaffolds and different trainings should be given to the people who will inspect the scaffolds.

Regulation on Health and Safety Conditions in the Use of Work Equipment' ARTICLE: 11 and Annex: II Article: 4.3.6, it has become a legal obligation for the persons who will carry out the supervision and inspection work before the installation, dismantling and use of the scaffolds to receive adequate training and to carry out inspections according to the installation - dismantling plans.

Who Provides Scaffolding Training?

There are many certification companies that provide scaffolding training. We recommend that you prefer accredited organisations that issue e-government approved certificates. You can easily reach the companies that provide scaffolding training with a short search on the internet. Although there is no exact number of these trainings, the prominent ones are as follows;

a- Scaffolding Inspection (Inspection) Training / Scaffolding Controller Training

These trainings can be given under different names. Scaffolding inspection training, scaffolding inspection training, scaffolding controller training, scaffolding inspector training, scaffolding inspector / inspector training.

These trainings are carried out in order to ensure that the personnel who will inspect the scaffolds during scaffolding installation, use and dismantling gain the necessary knowledge and skills for the persons in charge of the control and approval process of the scaffolds. A certificate is obtained as a result of the training.

b- Scaffolding Supervisor Training

The aim of scaffolding supervisor training; In the work on the scaffolding

Taking measures quickly and accurately,

Conducting inspections in a quality and complete manner,

Reducing injuries and fatalities to zero or minimising them

can be listed as. For this reason, these trainings are given in order to ensure that the people involved in the controls, trainings and inspections of the employees working on the scaffolding have knowledge and experience on the subject. At the end of the training, 'scaffolding supervisor certificate' certificate is obtained.

c- Scaffolding Installation Personnel Training

The purpose of these trainings is to ensure that the work done at height is safe, to qualify the personnel who can ensure compliance with occupational health and safety conditions, to separate the skilled people from the novices and to certify the experienced people. As a result of this training, a 'Scaffolding Installation Personnel Certificate' is obtained from an accredited organisation. In addition to this, documents and trainings are also required;

Vocational Qualification Certificate approved by the Ministry of National Education

Occupational Health and Safety Training

Work at Height Training (Theoretical and Practical)

Rope access training (IRATA 3 and/or SPRAD certified trainers)

Scaffolding erection / scaffolding dismantling training (Theoretical and Practical)

First Aid training

Emergency drills

Accident and aftermath drills

Suspended personnel rescue drill

On-the-Job OHS Talks (Toolbox)

3- Scaffolding Control Form

a- What is a scaffolding control form?

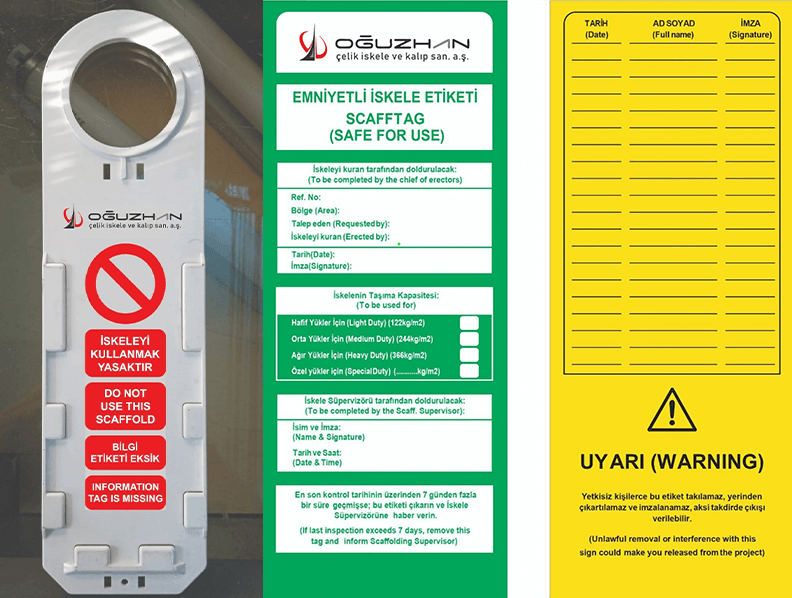

As the work on the scaffolding system continues, regular control of scaffolding materials is a matter to be considered. The document prepared to carry out these controls mentioned in the Regulation is called '' Control Form''.

b- How often and when should scaffolding be checked?

According to the Regulation on Occupational Health and Safety in Construction Works, scaffolding should be checked in the following cases:

Before starting to use,

At least once a week,

When it is modified,

When not used for a certain period of time,

When exposed to adverse weather conditions such as seismic shaking, strong winds or other conditions that may affect its stability and stability.

c- Who prepares the scaffolding control form?

In the Guide for Safe Working on Facade Scaffolds prepared by the Ministry of Family, Labour and Social Services, General Directorate of Health and Safety, it is recommended that the 'competent person' to be appointed by the employer should fill in the scaffolding control form. >You can review it here.

d- Example of scaffolding control form

Here you can access the sample> scaffolding control form prepared by the Ministry. This form may vary according to each company and can be improved.

4- Scaffolding Static Calculation Report

a- What is scaffolding static calculation?

The calculations made in order to measure the strength and carrying capacity of scaffolding systems against the forces that may come on them under varying working conditions are called "Scaffolding Static Calculation".

b- who makes the static calculation of scaffolding?

Civil engineers or static project engineers prepare it. In order to be a static project engineer, it is necessary to graduate from the Civil Engineering programme of universities. Scaffolding static calculation has become a sector in itself. Many experienced engineering companies provide this service.

c- scaffolding static calculation example?

Here you can find an example of scaffolding static calculation. It can be prepared as different presentations according to the programmes used by civil engineers.

5- Scaffolding Compliance Report

a- What is a scaffolding suitability report?

'Scaffolding conformity report' is defined for the 3 separate reports mentioned below. Therefore, what is intended to be said should be distinguished very well. These 3 reports are as follows;

Scaffolding conformity report?

If it is requested to prepare a report that the scaffolds are safe and in accordance with the legislation; For this, TS EN 12810-1 certificate and Product Manual are requested from the manufacturer and a report on compliance can be issued based on them.

Scaffolding Installation and Use Conformity Report?

A report can be prepared to determine that the scaffolds that have reached the construction site are installed in accordance with the 'scaffold erection, use and dismantling plan' prepared. This report can be called the scaffolding erection and use conformity report.

Periodic Control Compliance report of the scaffold?

It is the report prepared by the company or engineers performing periodic inspections on which tests and procedures were carried out during the inspection phase. As a result of this report, it can also be called 'periodic control conformity report' as it is stated that the scaffolding system is suitable or unsuitable. (Periodic control is also examined as a separate title below.)

6- Risk Assessment / Risk Analysis for Scaffolding

a- What is risk assessment / risk analysis?

Risk analysis; It is the process created to estimate the magnitude of various risks arising from working conditions in workplaces or construction sites or from the environment and conditions in the execution of the work and to decide whether the risk is acceptable or not, taking into account the adequacy of existing controls.

Occupational health and safety must be effective in order to prevent accidents on scaffolds. With risk assessments, hazards are identified and the causes of occupational accidents are indicated. In addition, it is tried to prevent which occupational diseases may occur by taking the most accurate measures by predicting which occupational diseases may occur.

b- Who performs the risk assessment / risk analysis?

Risk assessment is carried out by a team formed by the employer. The risk assessment team consists of the following.

Employer or employer's representative.

Occupational safety specialists and workplace physicians who carry out health and safety services at the workplace.

Employee representatives at the workplace.

Support staff at the workplace.

Employees who are determined to represent all units in the workplace and who are knowledgeable about the work carried out in the workplace, existing or potential sources of danger and risks.

The employer may receive services from persons and organisations outside the workplace to support this team when needed.

The coordination of risk assessment activities can also be provided by the employer or a person assigned by the employer from within the team.

The employer shall provide all necessary needs such as tools, equipment, space and time for the person or persons assigned in the risk assessment studies to fulfil their duties, and shall not restrict their rights and powers due to the performance of their duties.

The person or persons assigned in risk assessment studies shall protect and keep confidential the information and documents provided by the employer.

(OCCUPATIONAL HEALTH AND SAFETY RISK ASSESSMENT REGULATION - Official Gazette Date: 29.12.2012 Official Gazette No: 28512) www.oguzhaniskele.com

c- Is there a penalty for not preparing risk assessment / risk analysis?

Yes, there is, and a fine is imposed separately for each month the contravention continues. To learn the current fine amount, you can check the article titled 'Administrative fines to be applied in 2023 according to the OHS law No. 6331; Article 10- Risk assessment, control, measurement and research'.

d- Example of scaffolding risk assessment? Scaffolding risk analysis example?

Here you can access the form prepared for the example> 'scaffolding risk analysis assessment example'. This is just a sample form to give an idea. Each construction site may have its own unique conditions and risks, so risk assessments should be carefully prepared specifically for the construction site.

After reviewing the scaffolding risk assessment example, you can find sample content prepared for scaffolding in accordance with this form below; scaffolding risk analysis example,

For example, you can enter this in a line;

* FIELD; General / Field,

* SOURCE OF DANGER; Scaffolding and working on scaffolding.

* DANGER; Scaffolding legs do not fully fit to the ground

* RISK; Collapse of the scaffolding

* O= Probability Score

* S= Severity Score

* MINIMISING / PREVENTIVE ACTIVITY; Not starting work before the scaffolding legs are inspected

* RESPONSIBLE PERSON; Employer / Employer's Representative

The risk related to the hazard mentioned here, 'Failure of the Scaffolding Legs to Fit on the Ground', is not only the risk of 'collapse of the scaffolding'. There are also the following risks;

The materials on the scaffolding falling down

Fall of a worker on scaffolding

Collapse of the scaffolding on other workers

A separate line should be opened and evaluated for each risk. The hazard is the same but the risks are different. And for all risks, the probability, severity, risk score and priority order are numbered.

To give an idea, some of the other potential HAZARDS that may be related to scaffolding can be as follows;

Failure to Fully Assemble Scaffolding Crosses

Lack of Landing and Exit Stairs

Lack of Platform Railings

Carrying capacity not specified on the scaffolding

Failure to Wear Seat Belt

Dismantling

Risks should be identified for all these hazards and a separate line should be opened for each risk and a risk score should be determined. (The sample risk analysis data mentioned above is only intended to give an idea).

7- Scaffolding Periodic Control / Scaffolding Periodic Inspection

a- What is scaffolding periodic control?

Periodic Control (Periodic Inspection) is the process of checking the work equipment (scaffolding systems, since our subject is scaffolding) at regular intervals, taking into account the "Regulation on Health and Safety Conditions in the Use of Work Equipment" and related standards.

It should not be forgotten that; In order to minimise the risks of accidents caused by scaffolding systems, periodic inspection at regular intervals (every 6 months) is a financial, moral and legal advantage for employers.

b- What is the scaffolding periodic control regulation, how can I access it?

The regulation prepared by the Ministry of Labour and Social Security to determine the minimum requirements to be complied with in terms of health and safety regarding the use of work equipment in the workplace is also referred to as the Scaffolding periodic control regulation within the sector as it is within the scope. You can access this regulation in its entirety here;

c- Who performs the periodic control of scaffolding?

The answer to this question is published in the >Official Gazette. Namely; The obligation of the employer

ARTICLE 5 - (1) Employers who are obliged to carry out periodic controls of work equipment must check that the persons authorised to carry out periodic controls are from the relevant branches listed in Annex-III of the Regulation and have a valid registration number in the EKİPNET system. www.oguzhaniskele.com

Periodic inspections of scaffolds are carried out by graduates of civil and mechanical engineering and architecture departments of engineering and architecture faculties, machine and construction technicians or high technicians, and shipbuilding engineers in shipbuilding works.

In other words, engineers and technicians registered in the EKİPNET system can perform these controls. EKİPNET: It is a programme for the registration and tracking of persons authorised to carry out periodic inspections/examinations of work equipment.

Information; Engineers and technicians who are successful in the exam after the two-day training by TSE are registered in this system and receive their certificates. Those registered in the system can be queried from EKİPNET system in e-government. No one who is not registered in the EKİPNET system can perform scaffolding periodic controls.

d- How long is the scaffolding periodic control period?

In the 'Regulation on Health and Safety Conditions in the Use of Work Equipment', it is clearly stated as the periodic control of scaffolding and 6 months is determined as the maximum control period unless the period is specified in the standards. In other words, scaffolds should undergo periodic control every 6 months.

e- Scaffolding periodic control / inspection report?

It is the report prepared by the company or engineers performing periodic inspections on which tests and procedures were carried out during the control phase and whether the scaffolding system is suitable according to the test results. You can find detailed information about the content of this report in the following two articles.

f- How is scaffolding periodic control done?

The answer to the question of what is done in scaffolding periodic control is very curious. According to the application information we receive from the field in periodic controls, we can summarise what is done as follows;

General Control of Scaffolding

Review and approval of installation design

Performing visual quality controls

Performing functional controls

Photography

Load test

g- Sample Scaffolding periodic control form / content?

This form is the form that constitutes the scaffolding periodic control report. Many certification and engineering companies provide report services. Each company can create this form uniquely for itself. In order to satisfy your curiosity, what is generally included in this form is listed below;

Manufacturer of the scaffold, owner of the scaffold, technical specifications of the scaffold, regulations and standards on which the control is based, place of inspection, inspection phase, inspection types, inspection types, report no, control date, report date, validity period, explanations of the examinations applied, participants in the inspection, product photographs taken from the field, identified nonconformities, surveillance result and follow-up of nonconformities, results of the inspection, expert and technical manager signatures, etc.

D- RECYCLING PHASE

1- What happens to scrap scaffolds?

The scaffolds that have spent their life on construction sites have been bent, twisted, corroded and eventually become unsuitable to the level that cannot pass the inspections. Even at this stage, scaffolding systems bring one last gain. They are sold to recycling companies as scrap scaffolding. At the end of our article, we can say that in order to smile a little; there is Reincarnation in scaffolding systems :) They have had and will have a previous life and a next life...

This article has been an article that we, as Oguzhan Steel Scaffolding and Mould San. A.Ş. It has been an article that we have laboured on and compiled the adventure of scaffolding. Please do not copy it without permission. We hope you have found answers to the questions in your mind. If this article was useful to you, you can contribute to us by sharing the link to our page on your social media accounts. Thank you.

Our Products

Corporate

Products

© Copyrights Reserved 2026