GENERAL FEATURES OF TOWER TYPE SCAFFOLDING SYSTEM:

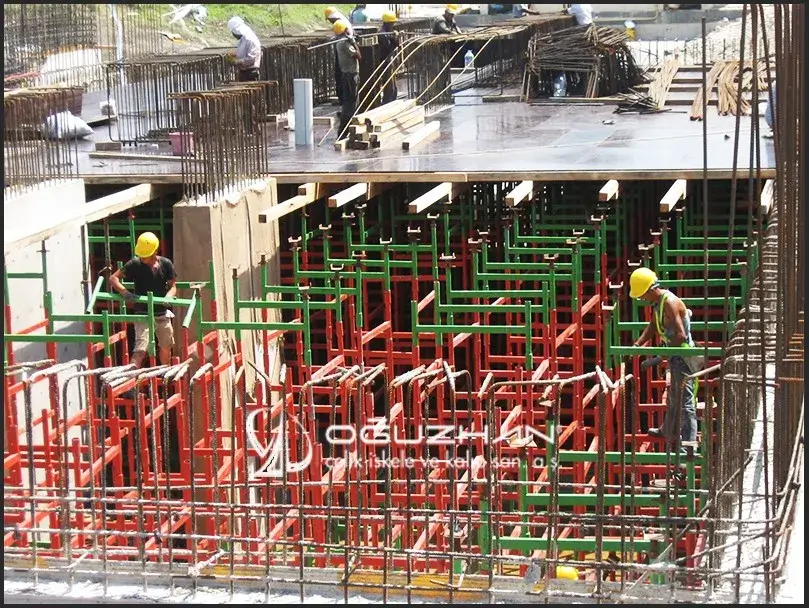

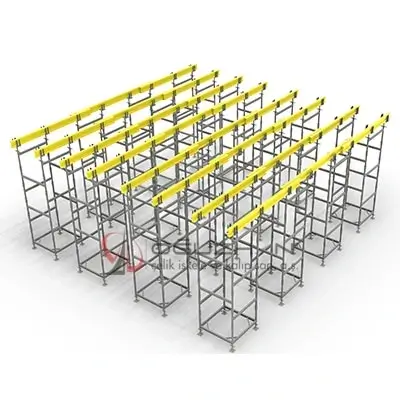

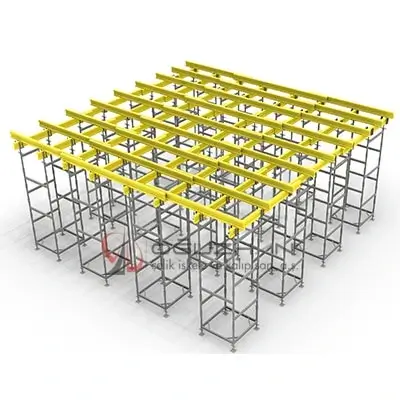

What is Tower Type Scaffolding? Tower Type scaffolding system is also known as Tower Type scaffolding system. It is used as a load scaffolding under the formwork. It is a formwork system with a high carrying capacity. 100x100cm or 120x120cm dimensions, max. It can be installed up to 12 meters high.

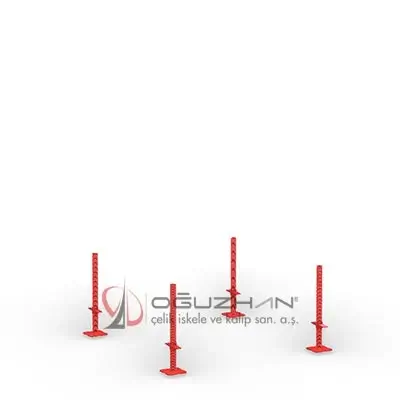

Tower Type scaffolding system; Lower Adjustment Shafts consist of Square Frame (Lower/Upper Frame), Main Frame with Sleeve, End Frame with Sleeve, Cross Member with Sleeve and Upper Adjustment Shafts. (Headings are in the form of 4-Way Header or U Header.)

In the Tower Type scaffolding system, installation and dismantling can be done without the need for any connection parts (wedge, pin, cup, etc.). Thanks to the staggered and interlocking pipe system, it is a practical system that does not require extra labor.

Tower Type scaffolding system; After each pair of main frames added to the initial square frame, it is continued to the desired height by rising 50 cm as standard. In the last stage, the mold level is adjusted with the upper adjustment spindles.

The Tower Type scaffolding system is built as independent towers. Cross members can also be used if towers need to be moved by crane. Cross members are produced on special request and are not included in the normal system. It can be preferred to be used for security in high systems.

Our Tower Type Scaffolding Materials are produced as OĞUZHAN® brand in accordance with TSE EN ISO 3834-2 Quality Conditions Standard for Melting Welding of Metallic Materials.

The pipes used in the production of Tower Type scaffolding are manufactured from pipes that have undergone mechanical and chemical tests and comply with TSE EN 10219-2 Structural Steel Pipe Standard.

Annotation

Access (Facade) Scaffolding Systems ….…. | Shoring Scaffolding Systems …...… ……. |

| Ring-Lock Scaffolding | Table Type H Scaffolding |

| H Type Safety Facade Scaffolding | Tower Type Scaffolding |

| Italy Type - Safety Facade Scaffolding | Cup-lock Scaffolding |

| Mobile Scaffolding Tower | Shoring Telescopic Prop System |

Column and Wall Formwork Systems ……. | Safety Systems ……………… ….…………... |

| Single Side Formwork | Safety Barrier System (Edge Protection) |

| Steel Surface Formwork | Safety Net System |

| H20 Beam Formwork | Material Transfer Platform System |

Special Formwork Systems ……… …………. | Accessories ……….…..…… ….……..….…… |

| Steel Slab Board | Auxiliary Work Equipment |

| Patterned Garden wall Formworks |